Car Magazine

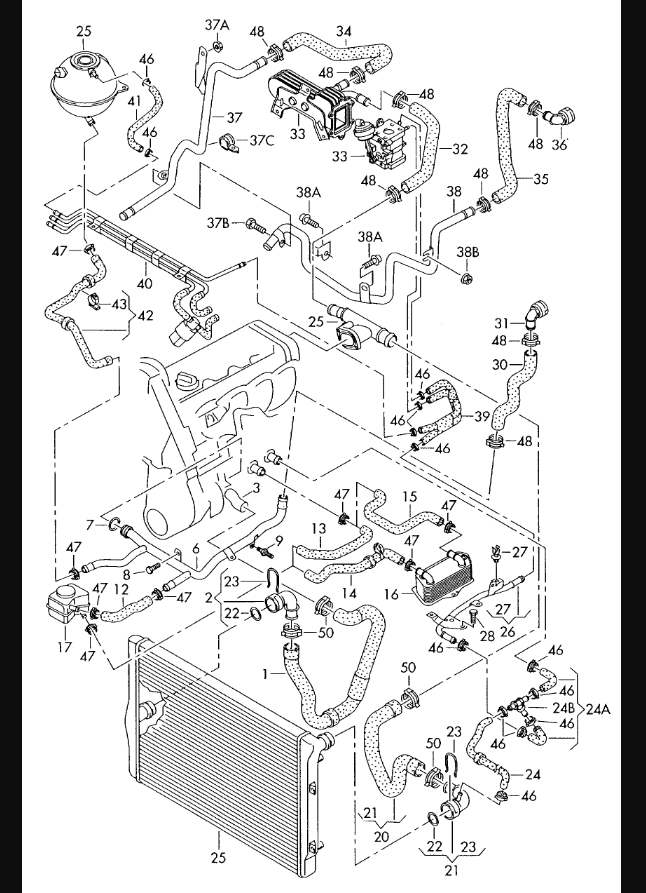

VW 2.0 Engine Parts Diagram

VW 2.0 Engine Parts Diagram – on our site you will find the best spare parts and accessories for cars and motorcycles

SELECT YOUR VEHICLE'S BRAND AND MODEL TO FIND ALL COMPATIBLE PRODUCTS ON RACEXT.

VW 2.0 Engine Parts Diagram

Before purchasing our products, it is advisable to read the product sheet. If in doubt, do not hesitate to contact us, we will be happy to help you choose the product that best suits your needs

If you are looking for high quality products for your car or motorbike, look no further. We are sure you will find the perfect product for you at Racext. Do not hesitate to contact us with any questions or requests. We are here to help you make your vehicle perfect.

VW 2.0 Engine Parts Diagram

VW 2.0 Engine Parts Diagram : Block

The block, a fundamental cornerstone of the Volkswagen 2.0 engine, is a testament to engineering excellence and precision. Crafted with meticulous care, this block boasts a robust and unyielding cast iron composition. Its closed-deck design is a marvel of structural engineering, comprising six meticulously aligned cylinders that form the heart of this powerhouse.

This structural arrangement is not merely an aesthetic choice but rather a critical element in enhancing the engine’s integrity and unwavering durability. Each cylinder is meticulously cast and honed to exacting specifications, ensuring optimal combustion efficiency and minimal wear over time.

To address the engine’s lubrication needs with the utmost precision, a wet sump system is seamlessly integrated into the design. This system operates with surgical precision, relying on a separate oil pan and a high-performance oil pump. The pump is a marvel of engineering, orchestrating the symphony of lubrication that safeguards the crankshaft and camshafts’ intricate movements.

Now, let’s delve into the ingenious innovation that resides within this block: the chain-driven overhead camshafts (OHC). For every cylinder bank, an OHC system reigns supreme, choreographing the ballet of intake and exhaust valve actuation with impeccable timing. The precision of these camshafts is nothing short of awe-inspiring, ensuring the engine’s harmonious operation with split-second accuracy.

To put it simply, the block is more than just the engine’s foundation; it is a testament to Volkswagen’s commitment to engineering perfection. It underpins the entire powerplant, its cast iron strength resonating with the enduring legacy of German engineering. This block is the canvas upon which the symphony of combustion is painted, and its design choices are a harmonious blend of structural integrity, precision, and unwavering durability.

VW 2.0 Engine Parts Diagram : Crank

The crankshaft, often referred to as the “heart” of the Volkswagen 2.0 engine, is nothing short of a mechanical marvel. Its role in converting reciprocating motion into the cherished rotational power that drives your vehicle is a testament to the precision and craftsmanship that Volkswagen engineers have poured into this essential component.

At the heart of it all, the crankshaft is responsible for orchestrating the symphony of motion within the engine. This vital component is not merely a rod of metal; it is a masterpiece of engineering, meticulously designed to exacting specifications. Its intricate connection to various engine components, including the pistons, camshaft, valves, and oil pump, transforms its rotational motion into the dynamic force that propels your vehicle forward.

Delving into the details of this engineering marvel, we uncover a world of precision and complexity. The crankshaft comprises a multitude of critical elements, each meticulously crafted to ensure a harmonious dance of components within the engine.

Rod Journals: These unassuming yet indispensable features are found on both sides of each connecting rod. They are the pivot points that allow for the smooth rotation of the crankshaft. As they traverse their cycle from top dead center (TDC) to bottom dead center (BDC), they are driven by connecting rods attached to pistons inside the cylinders. The design and dimensions of these rod journals are nothing short of engineering excellence, ensuring frictionless movement and minimal energy loss during each rotation.

Crankshaft Journals or Main Bearings: Unlike their counterparts, the rod journals, these components do not engage in a perpetual rotation. Instead, they remain steadfast as the crankshaft rotates past them during operation. The main bearings serve as the unwavering foundation upon which the entire crankshaft relies for its stability and smooth operation. Precision machining and perfect alignment of these main bearings are paramount, as any deviation could disrupt the engine’s delicate equilibrium.

Crankpin: Picture this as the point where one end of the connecting rod forms a secure attachment via a pin bearing. This connection allows the connecting rod to execute its graceful back-and-forth movement while being driven by the cylinder’s piston. These components, often referred to as main bearings, bear this name because they stand as guardians between two main bearings, nestled inside the oil sumps. The orchestration of these elements is nothing short of engineering ingenuity, ensuring that the engine operates in perfect harmony.

Main Bearing Caps: These unassuming yet indispensable components serve a multitude of purposes within the engine’s intricate ecosystem. They provide unwavering support for the mainshaft bearings, preventing them from bowing under the weight of the engine’s mechanical ballet. Moreover, they play a pivotal role in ensuring access when necessary for service work, such as the replacement of aging seals or worn-out components. These caps are an engineering marvel in themselves, embodying the delicate balance of strength and precision.

The crankshaft is not merely a component; it is the embodiment of precision engineering. Its intricate dance with connecting rods, pistons, and valves creates the mesmerizing symphony of power that propels your Volkswagen 2.0 engine forward. The devil is truly in the details, and every element of the crankshaft’s design and construction has been meticulously crafted to ensure optimal operation, efficiency, and reliability. It is, without a doubt, the beating heart of your engine, powering every journey with German-engineered excellence.

VW 2.0 Engine Parts Diagram : Oil pump – crank driven

The intricacies of the oil pump in the Volkswagen 2.0 engine reveal an engineering marvel that ensures the lifeblood of the engine, its lubrication, is delivered with unmatched precision. The oil pump is ingeniously driven by the crankshaft, making it an integral part of the engine’s mechanical orchestra.

Driven by the Crankshaft: The oil pump’s connection to the crankshaft is a testament to the harmonious collaboration of engine components. As the crankshaft undergoes its rotational journey, it transfers this kinetic energy to the oil pump, setting in motion a meticulously calibrated sequence of events.

Single-Stage Positive Displacement Pump: The oil pump’s design follows the principle of positive displacement, a hallmark of reliability and efficiency. It operates as a single-stage pump, deftly drawing in oil from the sump and propelling it forward with unwavering force. Every rotation of the pump results in a precisely measured volume of oil being delivered to the engine’s critical components, ensuring they remain adequately lubricated.

Variable Displacement Mechanism: At the heart of the oil pump’s excellence lies its variable displacement mechanism. This engineering innovation is tasked with adjusting the volume of oil delivered based on the engine’s demands. Whether cruising on the highway or pushing the limits on the track, this mechanism ensures that the right amount of oil is always at the ready. It’s a testament to the engine’s efficiency, conserving power when it’s not needed and delivering it with precision when required.

Efficiency Beyond Measure: Even when the engine operates under maximum load, the oil pump’s power consumption remains astonishingly efficient. Consuming a mere fraction of the engine’s total horsepower, approximately 1/2 horsepower, it stands as a testament to the meticulous engineering that defines Volkswagen’s commitment to excellence.

Isolated Excellence: The oil pump assembly is a paragon of isolation within the engine’s complex ecosystem. Nestled within its dedicated casing, it remains insulated from the surrounding components. Gaskets, seals, and bearings form an impenetrable barrier, ensuring that the oil pump’s operation is unhindered by any external influences.

The oil pump’s role in the Volkswagen 2.0 engine extends far beyond mere lubrication; it embodies precision, efficiency, and reliability. Its unwavering commitment to delivering the lifeblood of the engine is a testament to the meticulous engineering that defines every component of this automotive masterpiece. With the oil pump in place, the engine operates with the assurance that each vital part receives the nourishment it requires, propelling the vehicle with unbridled power and German-engineered excellence.

VW 2.0 Engine Parts Diagram : Oil pump – camshaft driven

The camshaft-driven oil pump in the Volkswagen 2.0 engine represents a refined and intricately woven mechanical ballet, where every component plays a crucial role in the engine’s operation. Let’s dive deeper into the symphony of engineering that powers this remarkable system.

Camshaft-Driven Excellence: At the heart of this configuration is the seamless marriage between the camshaft and the oil pump. As the camshaft revolves within the engine block, its purpose extends beyond valve actuation. It takes on the additional responsibility of driving the oil pump, a testament to the ingenious design that maximizes efficiency.

Precise Placement: The oil pump finds its home within the engine block, nestled among the array of components that make up this powerhouse. Its strategic placement ensures that it can fulfill its role as the lifeblood provider to critical engine parts.

The Sprocket Duo: The oil pump’s camshaft-driven mechanism relies on a duo of sprockets—an intricately designed pair that synchronizes the pump’s operation. The drive sprocket, connected to the camshaft, acts as the engine’s conductor, orchestrating the flow of oil. The driven sprocket, an equally critical player, receives the directives from its counterpart and translates them into precise movement.

Timing Belt as the Conductor: What sets this configuration apart is the use of the timing belt as the driving force for the camshaft. The timing belt serves as the conductor of this mechanical orchestra, ensuring that every component operates in perfect harmony. Its role is both critical and delicate, as it synchronizes the engine’s internal movements, from valve timing to oil pump operation.

Synchronized Precision: The coordination between the camshaft, timing belt, drive sprocket, and driven sprocket is a testament to engineering precision. Every revolution of the camshaft translates into the precise rotation of the oil pump. This synchronization ensures that the right amount of oil is delivered to critical engine components at the right moment, optimizing lubrication and performance.

This camshaft-driven oil pump configuration is more than a mechanical design; it’s a testament to Volkswagen’s commitment to engineering excellence. It represents the harmonious collaboration of components working in unison to deliver optimal performance and reliability. As the timing belt orchestrates this symphony of motion, the engine benefits from a steady and calculated flow of oil, ensuring it operates with German-engineered precision and efficiency.

VW 2.0 Engine Parts Diagram : Piston cooling nozzle and oil jet

The intricacies of piston cooling within the Volkswagen 2.0 engine reveal a finely tuned system designed to keep critical components operating within their optimal temperature ranges. This piston cooling nozzle and oil jet arrangement is not merely a feature; it’s a testament to precision engineering and the relentless pursuit of efficiency and performance.

Piston Cooling Nozzle: Positioned strategically within the combustion chamber, the piston cooling nozzle plays a pivotal role in regulating the temperature of the engine’s pistons. It’s an unsung hero, tirelessly working to prevent overheating and potential damage to these crucial components. Crafted from materials with exceptional heat transfer capabilities, these nozzles ensure that the pistons remain within their ideal temperature range, even under the most demanding conditions.

Direct Connection to the Oil Jet: What sets this system apart is its direct connection to an oil jet. The oil jet, a fundamental element of the engine’s oil system, acts as the conduit for the lifeblood of the engine—lubricating oil. This connection is not a mere convenience; it’s a calculated engineering decision. It ensures that the cooling process is not only effective but also seamlessly integrated into the overall lubrication system.

A Holistic Oil System: The oil jet is not an isolated component but an integral part of a comprehensive oil system that encompasses several critical elements. The oil system includes an accumulator, filter, pressure regulator, and lubricating pump. Together, these components form a symphony of lubrication, ensuring that every part of the engine receives the precise amount of oil it requires.

Accumulator: The accumulator stores pressurized oil, ready to be dispatched at a moment’s notice. It serves as a reservoir of lubrication, ensuring that the engine’s critical components are never starved of the vital oil they need to operate smoothly.

Filter: The filter is the guardian of the engine’s oil system. It stands as the first line of defense, removing impurities and contaminants from the oil before it embarks on its journey through the engine. This ensures that the oil remains clean and free of debris, prolonging the life of critical components.

Pressure Regulator: The pressure regulator is a masterful device that governs the flow of oil. It ensures that the oil is delivered at the right pressure, optimizing lubrication and preventing excess oil from inundating engine parts.

Lubricating Pump: The lubricating pump is the heartbeat of the oil system, tirelessly pushing oil through the intricate network of passages, channels, and nozzles. Its efficiency ensures that the engine operates with the precision for which Volkswagen is renowned.

In conclusion, the piston cooling nozzle and oil jet system within the Volkswagen 2.0 engine is not just a technical feature; it’s a testament to engineering excellence. It reflects a commitment to optimal performance, reliability, and efficiency. Every component, from the nozzle to the oil jet and the entire oil system, works in harmonious unison to ensure that your engine operates within its ideal temperature range and continues to deliver the performance you expect from German-engineered excellence.

VW 2.0 Engine Parts Diagram : Pistons & con rods

The dynamic duo of pistons and connecting rods within the Volkswagen 2.0 engine are not just components; they’re the epitome of precision engineering, where strength meets efficiency, and form follows function.

Pistons: Crafted from lightweight yet durable aluminum, the pistons are a testament to engineering excellence. This choice of material strikes the perfect balance between strength and weight savings, contributing to the engine’s overall performance and efficiency. But it doesn’t stop there; these pistons boast a flat crown shape—a seemingly subtle design choice that carries profound implications. This ingenious design reduces friction between the piston rings and cylinder walls, ensuring that every combustion cycle operates with the utmost efficiency. However, the journey from raw material to precision component involves forging, a meticulous process that guarantees precise tolerances. These forged pistons are the unsung heroes of the engine, their every movement orchestrated with German-engineered precision.

Connecting Rods: In the realm of connecting rods, precision is the name of the game. These components, also forged with meticulous care, take efficiency to the next level. Unlike their iron counterparts, they’re lightweight, ensuring that the engine’s internal movements are as efficient as possible. But efficiency doesn’t mean sacrificing strength. In fact, connecting rods can be further strengthened through the use of materials like powdered metal or high-strength steels, including the remarkable titanium alloy. These materials are not just options; they’re the embodiment of engineering innovation, reinforcing the connecting rods to withstand the tremendous forces they’re subjected to.

In essence, the pistons and connecting rods within the Volkswagen 2.0 engine are not just parts; they’re precision instruments that elevate the engine’s performance to the highest echelons. Crafted with a keen understanding of materials science and engineering principles, they embody the relentless pursuit of efficiency and reliability. With each piston’s graceful movement and every connecting rod’s unwavering strength, your engine operates with the precision and power that only German engineering can deliver.

VW 2.0 Engine Parts Diagram : Cylinder head

The cylinder head, a vital cog in the intricate machinery of the Volkswagen 2.0 engine, is more than just an enclosure; it’s a sanctuary for precision components that orchestrate the engine’s performance.

Valves: At the heart of the cylinder head lies the valves. These meticulously crafted components control the ingress and egress of air and fuel, a task that demands precision and reliability. The valves are the gatekeepers of combustion, opening and closing with German-engineered precision to ensure optimal performance.

Valve Seat Inserts: Nestled within the cylinder head, the valve seat inserts play a critical role. They create a seal against the piston rings, a duty that requires perfection. The marriage between the valve seat inserts and the piston rings ensures that combustion is contained and controlled, contributing to the engine’s efficiency and power.

Valve Guides: Guiding the valves on their journey is another crucial task. Valve guides provide the necessary stability and alignment, ensuring that the valvetrain operates flawlessly. They are the unsung heroes, silently orchestrating the valves’ movements with the precision of a maestro.

Valve Springs: Valve springs are the sentinels of the valves, ensuring they close with the right amount of force. Their role in maintaining pressure on the valves when they are closed is indispensable. This pressure ensures a perfect seal between the piston and the cylinder wall, a seal that is critical for performance and efficiency.

Valve Stems with Oil Wipe Rings: The valve stems are more than just mechanical components; they are engineered with a delicate touch. Equipped with oil wipe rings, they serve as cushioning material, preventing damage when opening or closing. These rings are the guardians of valve stem integrity, ensuring that they continue to function at peak performance.

In summary, the cylinder head is not just a housing; it’s a haven for precision. Within its confines, valves, valve seat inserts, valve guides, valve springs, and valve stems with oil wipe rings collaborate with meticulous precision. Their collective effort ensures that your VW 2.0 engine operates with the excellence and performance that you expect from German engineering. It’s a symphony of components, each playing its part to perfection, resulting in a harmonious blend of power and reliability.

VW 2.0 Engine Parts Diagram : Inlet ports

The inlet ports, often overlooked but vital components within the Volkswagen 2.0 engine’s cylinder head, are the gateway to the engine’s performance and efficiency. Let’s delve into the intricacies of these ports and uncover the engineering brilliance behind them.

Function as Gateways: Inlet ports are not mere openings; they are the gateways through which the air/fuel mixture enters the combustion chamber. Their role in this process is pivotal, as the efficiency of this entry directly impacts the engine’s performance.

Shapes for Efficiency: In the world of inlet ports, there’s no one-size-fits-all approach. They can assume either circular or rectangular shapes, each meticulously designed to optimize the flow of fuel and air. Circular ports offer a natural path for uniform mixture distribution, while rectangular ones provide a broader surface area for increased airflow. These shape options reflect the fine-tuning of the engine’s design to meet specific performance requirements.

Inclined Walls for Precision: What sets these ports apart is the inclination of their walls. These walls are not arbitrary; they are designed with a purpose. The incline serves a dual function—guiding the fuel/air mixture from one side of the port to another while preventing interference from hot gases lingering from the previous combustion cycle. This strategic design choice ensures that the incoming mixture remains pure and untainted, ready to combust with precision.

Efficient Cooling: The role of inlet ports extends beyond fuel and air delivery; they also play a part in engine cooling. Their strategic positioning helps direct the incoming mixture away from critical engine components that require cooling. This prevents overheating and ensures that the engine block maintains its optimal temperature.

In conclusion, the inlet ports within the Volkswagen 2.0 engine are not mere openings; they are precision-engineered components that enhance performance and efficiency. Their shape, design, and strategic placement reflect the relentless pursuit of excellence in German engineering. As these ports guide the fuel/air mixture into the combustion chamber, they do so with precision, ensuring that your engine operates with the efficiency and power for which Volkswagen is renowned.

The mechanisms for supplying oil to both the inlet and exhaust valve stems within the Volkswagen 2.0 engine are a testament to precision engineering, ensuring that every vital component operates with the lubrication it deserves.

Inlet Valve Stems – Drip Feed Mechanism: The inlet valve stems receive their essential oil supply through a meticulously controlled drip feed mechanism. This system is under the watchful eye of the camshaft, which orchestrates the process with German-engineered precision. The camshaft’s role is not limited to valve actuation; it also governs the delivery of oil to the inlet valve stems. This drip feed mechanism ensures that lubrication is delivered in the right quantities at the right time, optimizing the performance and longevity of these critical components.

Exhaust Valve Stems – Direct Supply: When it comes to the exhaust valve stems, a direct supply system takes center stage. This system employs flexible tubes that serve as the conduits for delivering oil to the exhaust valve stems. It’s a direct and efficient method, ensuring that lubrication reaches these components without delay. The direct supply system reflects an engineering decision that prioritizes efficiency and reliability, two hallmarks of German engineering.

VW 2.0 Engine Parts Diagram :

Conclusion

In summary, the oil supply mechanisms for both the inlet and exhaust valve stems within the Volkswagen 2.0 engine are not just functional; they are finely tuned systems designed to ensure optimal performance and reliability. Whether through the controlled drip feed mechanism for inlet valve stems or the direct supply system for exhaust valve stems, the engine benefits from a steady and calculated flow of oil. It’s a testament to engineering excellence that guarantees your engine operates with the precision and efficiency that you expect from German engineering.

In conclusion, delving into the intricacies of the Volkswagen 2.0 engine reveals a world of precision engineering, where every component plays a vital role in achieving peak performance. It’s not just an engine; it’s a symphony of finely tuned parts working in harmony to deliver the power, efficiency, and reliability that Volkswagen is renowned for.

Maintenance is Key: To keep your VW 2.0 engine running at its best, proper maintenance and care are paramount. Regular servicing, attention to detail, and adherence to recommended maintenance schedules are your engine’s best friends. This ensures its longevity and dependable operation for years to come.

Contact Us for Expert Assistance: We understand that the complexities of an engine can sometimes be overwhelming. If you have any questions, need guidance on maintenance, or seek further information about your VW 2.0 engine, please don’t hesitate to reach out to us. Our team of experts is here to assist you and ensure that your Volkswagen 2.0 engine continues to perform at its peak.

In the world of engineering excellence, Volkswagen’s 2.0 engine stands as a shining example. It’s not just an engine; it’s a masterpiece of precision, and it’s our pleasure to be your guide on this journey of mechanical marvel.

FAQ: Volkswagen 2.0 Engine – Unveiling the Mechanical Marvel

Welcome to our comprehensive FAQ section dedicated to the intricacies of the Volkswagen 2.0 engine. We’re here to address your queries, provide insights, and guide you through this remarkable piece of mechanical engineering. Let’s dive into the world of precision and performance.

1. What distinguishes the Volkswagen 2.0 engine from its predecessors?

The Volkswagen 2.0 engine is known for its improved efficiency, achieved through a lower compression ratio, ideal for enhanced fuel economy. It also features a larger turbocharger for more power at lower RPMs, ensuring better acceleration.

2. Can you explain the significance of the closed-deck block design?

Certainly. The closed-deck block design enhances structural integrity and durability. It provides a solid foundation for the engine, ensuring that it can withstand the rigors of high-performance driving.

3. How does the wet sump system in the Volkswagen 2.0 engine work?

The wet sump system employs a separate oil pan and pump. The pump maintains consistent lubrication for the crankshaft and camshafts, safeguarding their smooth operation.

4. What is the role of the crankshaft in the engine?

The crankshaft is the engine’s rotational powerhouse. It connects to the pistons, camshaft, valves, and oil pump. It’s a complex assembly that must align perfectly to ensure optimal engine operation.

5. How efficient is the oil pump in the Volkswagen 2.0 engine?

The oil pump is a single-stage positive displacement pump that consumes only about 1/2 horsepower even at maximum load. Its variable displacement mechanism efficiently pushes oil from the sump to the rocker arms and valve covers.

6. Can you explain the difference between crankshaft-driven and camshaft-driven oil pumps?

Certainly. In a crankshaft-driven oil pump, the pump is directly driven by the crankshaft. In contrast, a camshaft-driven oil pump is driven by the camshaft, which is indirectly connected to the crankshaft via the timing belt.

7. Why are piston cooling nozzles and oil jets crucial in the engine?

Piston cooling nozzles regulate piston temperature, preventing damage. These nozzles are connected to oil jets, which, in turn, are part of an oil system that ensures proper lubrication and cooling.

8. How are pistons and connecting rods optimized for performance?

Pistons are crafted from aluminum for strength and weight savings. They feature a flat crown shape that reduces friction. Connecting rods, also forged, are lightweight and can be further strengthened with materials like powdered metal or titanium alloy.

9. What are the key components housed within the cylinder head?

The cylinder head is home to valves, valve seat inserts, valve guides, valve springs, and valve stems with oil wipe rings. Each of these components plays a crucial role in controlling the flow of air and fuel and ensuring a proper seal.

10. What are inlet ports, and why are they designed in circular or rectangular shapes?

Inlet ports are openings in the cylinder head that allow air/fuel mixture to enter the combustion chamber. Circular and rectangular shapes are designed for maximum flow. The inclined walls guide the mixture and prevent interference from hot gases.

11. Can you explain the function of the baffle plate in the engine?

The baffle plate serves as a protective cover for the rocker shafts, housing holes for oil delivery to the valve train. It bolsters the engine’s structural integrity and ensures efficient oil distribution.

12. How do rocker shafts contribute to valve actuation?

Rocker shafts connect the camshaft to the valve rockers, enabling valve actuation. Their adjustability allows precise alignment with cam lobes, ensuring accurate valve timing.

13. What are the oil supply mechanisms for inlet and exhaust valve stems?

Inlet valve stems receive oil through a controlled drip feed mechanism driven by the camshaft. For exhaust valve stems, a direct supply system employs flexible tubes that connect to the valve stems.

14. How can I maintain and optimize the performance of my Volkswagen 2.0 engine?

Regular maintenance is key. Adhere to recommended servicing schedules, pay attention to detail, and consult your vehicle’s manual for guidance. Proper care ensures longevity and dependable operation.

15. Where can I get expert assistance or further information about my VW 2.0 engine?

Feel free to contact our knowledgeable team for any questions or guidance. We’re here to provide you with the expertise you need to keep your Volkswagen 2.0 engine running at its best.

16. What’s the significance of the variable displacement mechanism in the oil pump?

The variable displacement mechanism in the oil pump allows it to adjust the volume of oil it delivers, ensuring that the engine receives just the right amount of lubrication. This adaptability contributes to both efficiency and performance.

17. Can you elaborate on the importance of valve seat inserts and valve guides in the cylinder head?

Valve seat inserts serve as crucial sealing components. They ensure a tight seal between the piston rings and valves when closed. Valve guides, on the other hand, guide various valvetrain components, including pushrods and rocker arms, ensuring precise valve movement.

18. How does the Volkswagen 2.0 engine maintain efficiency and power balance with a larger turbocharger?

The larger turbocharger in the Volkswagen 2.0 engine provides more power and improved acceleration at lower RPMs. However, it’s important to note that larger turbos may exhibit some turbo lag, meaning they may take a moment to spool up at higher RPMs.

19. What are some common maintenance tasks to keep my Volkswagen 2.0 engine in top shape?

Routine maintenance tasks include regular oil changes, air filter replacements, spark plug inspections, and adhering to the manufacturer’s recommended maintenance schedule. These tasks are essential for preserving engine health.

20. How can I maximize fuel efficiency with my Volkswagen 2.0 engine?

To optimize fuel efficiency, ensure that your vehicle is properly maintained. Additionally, consider adopting eco-friendly driving habits, such as smooth acceleration and deceleration, maintaining steady speeds, and reducing unnecessary idling.

21. Are there any aftermarket upgrades available for the Volkswagen 2.0 engine?

Yes, there is a range of aftermarket upgrades available, including performance air filters, exhaust systems, and ECU tuning. However, it’s essential to research and choose reputable aftermarket parts to avoid compromising engine reliability.

22. What sets the Volkswagen 2.0 engine apart from engines in other vehicles?

The Volkswagen 2.0 engine is known for its German engineering excellence, offering a balanced blend of performance, efficiency, and reliability. Its unique design elements and attention to detail contribute to its distinct characteristics.

23. Can I perform basic maintenance tasks on my Volkswagen 2.0 engine myself, or should I always consult a professional?

While some basic maintenance tasks can be performed by vehicle owners, it’s advisable to consult a professional mechanic or follow your vehicle’s manual for more complex procedures. Professional guidance ensures that maintenance is done correctly and doesn’t void any warranties.

24. What’s the redline for the Volkswagen 2.0 engine, and why is it important?

The redline for the Volkswagen 2.0 engine is typically set at 6,500 RPM. It’s a crucial reference point that indicates the maximum safe rotational speed for the engine. Exceeding the redline can lead to engine damage, so it’s essential to stay within this limit during operation.

25. How can I identify potential issues with my Volkswagen 2.0 engine, and what should I do if I suspect a problem?

Listen for unusual noises, monitor warning lights on your dashboard, and pay attention to changes in performance or fuel efficiency. If you suspect a problem, consult your vehicle’s manual for guidance or seek assistance from a qualified mechanic promptly.

RACEXT QUALITY GUARANTEE

RACEXT QUALITY GUARANTEE

Every Racext performance product is thoroughly tested and guaranteed, even if it doesn’t feature a visible logo. Due to production and logistical reasons, some products may not carry the Racext branding directly on the item.

However, rest assured that all our products undergo rigorous quality checks and are backed by Racext’s commitment to performance and reliability.

EXCLUSIVE MANUFACTURING AND DISTRIBUTION

EXCLUSIVE MANUFACTURING AND DISTRIBUTION

Our trusted partners manufacture each product according to our specific technical requirements, ensuring that every item meets Racext’s high standards. All our products are exclusively sold by Racext and are not distributed by other companies.

Even though some of our partners commercialize similar products for cars, these items are not compatible with motorcycles due to distinct resistance and amperage requirements.

PRECISION-CALIBRATED CHIP TUNING DEVICES

PRECISION-CALIBRATED CHIP TUNING DEVICES

When it comes to our chip tuning devices, the resistance is precisely calibrated to be perfectly adapted to different vehicles, such as motorcycles. This ensures optimal performance, compatibility, and a smooth ride without any risk to your vehicle’s electronic systems.

Racext chip tuning devices are specially designed to meet the unique demands of motorcycle performance systems, guaranteeing that your bike runs efficiently and reliably.

This product is not certified, approved or homologated for use on public roads or highways in any country. It is intended solely for off-road use, closed-circuit racing, sports competition, or private testing purposes. Installation and use of this product on vehicles driven on public streets is strictly prohibited and may violate traffic laws, emissions regulations, or technical inspection requirements.

By purchasing this product, the customer acknowledges and agrees that:

- The product is sold “as is” for motorsport or off-road use only.

- It is not street-legal and must not be used on public roads under any circumstance.

- The seller (Racext) assumes no responsibility for any improper, illegal or unintended use of this product.

- The customer is solely responsible for verifying whether the installation and use of this product comply with local laws and regulations.

- This product may affect vehicle warranty and insurance if used outside of permitted contexts.

This notice applies regardless of the country in which the product is purchased or shipped, including (but not limited to) the United States, Canada, the European Union, the United Kingdom, Australia and New Zealand.

By proceeding with the purchase, you confirm that you have read, understood and accepted this disclaimer, and release the seller from any liability arising from misuse or unauthorized application of the product.

QUALITY STANDARDS ACROSS ALL PRODUCTS

QUALITY STANDARDS ACROSS ALL PRODUCTS

This high standard of exclusive design, manufacturing, and compatibility applies to all Racext products available for purchase. Every item in our catalog is crafted with the same dedication to performance, safety, and quality.

Disclaimer

TRANSPARENT SHIPPING POLICY

Cutoff time 22:00 (GMT+01:00) Central European Standard Time (Amsterdam)

Order Processing Time 1-3 days (Mon-Fri)

Delivery time 3-6 days (Monday-Friday)

Our orders are free of shipping costs.

We use the following shipping couriers:

- PostNL

- Dhl

- UPS

- DPD

- Cainiao

The customer will receive the tracking information in 1-3 days directly in his email. Please contact us if you have not received the email or check your spam emails

LEGAL DISCLAIMER: PRODUCTS INTENDED EXCLUSIVELY FOR SPORTING AND COMPETITIVE USE

Important: Before proceeding with the purchase or use of our sport exhausts, please read the following notice carefully.

The products sold through this website are intended exclusively for sporting and competitive use. This means they have been designed and manufactured to be used in controlled environments, such as closed circuits or areas designated for sporting competitions, where emission and noise regulations may differ from those applied on public roads.

Public Road Use Not Allowed: It is emphasized that the installation and use of these devices on vehicles intended for circulation on public roads may not be permitted under the laws of your reference country regarding emission and noise regulation, as they are not designed for road use but for sporting use.

Buyer’s Responsibility: It is the buyer’s responsibility to ensure that the use of the purchased products complies with all applicable laws and regulations. The buyer assumes all legal liabilities for any non-compliant use of the products, including the installation and operation of such devices on unauthorized vehicles or in ways that violate applicable laws.

By continuing with the purchase, the buyer acknowledges and agrees that the use of the products is limited to sporting and competitive contexts as defined above and assumes full responsibility for any legal consequences arising from improper use of the products.

VW 2.0 Engine Parts Diagram

Compatibility:

It is the responsibility of the customer to ensure that the product is compatible with their vehicle. We recommend consulting with a professional mechanic before purchasing to confirm compatibility. Racext is not responsible for any issues that may arise from the use of our products, including but not limited to damage to the vehicle or personal injury.

Warranty:

All of our products come with a 2-year warranty in accordance with international standards. If you experience any issues with your product within the warranty period, please contact us for assistance. The warranty does not cover damages caused by improper installation, misuse, or external factors such as accidents or natural disasters.

Returns

ABOUT US

ADDRESS: Creative Tower – Hamad Bin Abdulla Road – Office 4201 – Fujairah – U.A.E.

E-mail : info@Racext.com

Contact form : Get in touch

Phone : +971 58 859 1706

Company name : Digitanow International group FZe

Company Number : AE18048/2020

Tax registration number: AE18048 2020

Customer service : Monday to Friday from 9 a.m. to 8 p.m.

Terms and Conditions

This website provides only the product with well-indicated codes and specifications. Please rely on an experienced workshop for the installation and choice of the product. We do not assume any responsibility for errors in choice, installation, or programming of the devices.

*The price is intended for a single product

*Days are always working days

All guides on this website are for illustrative purposes only. For many products, the use of special tools may be necessary. We always recommend seeking the advice of a specialized repair center for the selection and installation or programming of products purchased anywhere. We do not assume any responsibility for damage to property or persons, or user errors in the application of a guide on this website or for any other occurrence.

Product is not original but fully interchangeable with it

All rights reserved. All trade names and logos are registered trademarks of the respective manufacturers indicated

The trademarks mentioned on this site are the exclusive property of the automotive companies and are used here exclusively to facilitate the search for vehicles by our customers. We do not assume any responsibility for damages to property or persons, or user errors in the application of a guide on this website or for any other occurrence.

Secure Payments

When making purchases on our website, you can be confident that your transaction is secure. All financial transactions are processed on the secure and certified servers of PayPal or Stripe. These platforms allow us to accept payments from all VISA, VISA ELECTRON, MAESTRO, POSTEPAY, AMERICAN EXPRESS, AURA, and DISCOVER credit cards.

Quality Guarantee

Choose safety, savings, and professionalism by choosing us. We offer top-level customer support that will never leave you alone during the pre- and post-purchase phases. We offer top-quality products and intelligent, secure savings. Don’t trust inexperienced sellers.

NOTE: In the event that the product is not available in stock, we reserve the right to issue a full and immediate refund.

[mailpoet_form id=”3″] Get 10% OFF and

Get 10% OFF and  FREE SHIPPING on any order with code: Bike10

FREE SHIPPING on any order with code: Bike10

Arabic

Arabic Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch English

English French

French German

German Greek

Greek Italian

Italian Japanese

Japanese Maltese

Maltese Norwegian

Norwegian Polish

Polish Portuguese

Portuguese Romanian

Romanian Serbian

Serbian Slovenian

Slovenian Spanish

Spanish Swedish

Swedish Need help?

Need help?