Blog, Car Magazine

Oxygen Sensor: 1, 2, 3, 4 Wire O2 Sensor Wiring Diagram

Oxygen Sensor: 1, 2, 3, 4 Wire O2 Sensor Wiring Diagram – on our site you will find the best spare parts and accessories for cars and motorcycles

SELECT YOUR VEHICLE'S BRAND AND MODEL TO FIND ALL COMPATIBLE PRODUCTS ON RACEXT.

Oxygen Sensor: 1, 2, 3, 4 Wire O2 Sensor Wiring Diagram

Before purchasing our products, it is advisable to read the product sheet. If in doubt, do not hesitate to contact us, we will be happy to help you choose the product that best suits your needs

If you are looking for high quality products for your car or motorbike, look no further. We are sure you will find the perfect product for you at Racext. Do not hesitate to contact us with any questions or requests. We are here to help you make your vehicle perfect.An oxygen sensor, also known as an O2 sensor or lambda sensor (λ), plays a crucial role in the operation of a vehicle by measuring the concentration of oxygen molecules present in the exhaust gas. This electronic sensor provides valuable data to the engine control unit (ECU), enabling it to effectively monitor and optimize the engine’s performance.

When it comes to monitoring oxygen levels in the exhaust system, the oxygen sensor in a car is an indispensable device. By constantly measuring the amount of oxygen in the exhaust gases, it assists in maintaining the engine’s efficiency and reducing harmful emissions. You can typically find the oxygen sensor situated within the exhaust system of the vehicle.

To understand how the oxygen sensor connects to the electrical system of a vehicle, a useful resource is an oxygen sensor wiring schematic. This schematic diagram visually depicts the connections between the oxygen sensor and the vehicle’s electrical components. It provides valuable information such as the precise location of the oxygen sensor, the type of sensor being used, and the color-coding of the wires. Additionally, the diagram might include the positions of other sensors and components that are closely associated with the oxygen sensor.

In this comprehensive guide, you will gain a deep understanding of oxygen sensor wiring diagrams, including those for one, two, three, and four-wire configurations. By studying these diagrams, you will be equipped with the knowledge needed to accurately interpret and work with the wiring of oxygen sensors in various vehicle setups. This knowledge will empower you to effectively troubleshoot, repair, or replace oxygen sensors when necessary, contributing to the optimal performance and eco-friendliness of your vehicle.

The Importance of Oxygen Sensors

Oxygen sensors, also known as O2 sensors, play a vital role in both vehicles and industrial emission control systems. These sensors are responsible for measuring the levels of oxygen present in the exhaust gases produced by combustion engines and other combustion processes.

The significance of oxygen sensors lies in their ability to provide real-time feedback to the engine control module (ECM) or other control systems. This feedback enables precise fuel control, leading to improved engine performance, enhanced fuel economy, and reduced emissions of harmful substances.

Without oxygen sensors, the ECM would struggle to accurately determine the appropriate amount of fuel required for efficient combustion. This would result in decreased fuel efficiency and increased emission levels, contributing to environmental pollution. Moreover, malfunctioning oxygen sensors can lead to various issues such as reduced engine power, higher fuel consumption, and increased release of pollutants into the environment.

In the emissions control system, there are two types of oxygen sensors: the front sensor and the rear sensor. These sensors are divided into bank 1 and bank 2, which correspond to different sides of the engine (b1s1, b2s1). The sensors continually monitor the emissions gases. If a sensor fails, it can trigger the check engine light (CEL) and generate a Diagnostic Trouble Code (DTC). This code can be read using a scan tool, helping to identify and diagnose the underlying problem.

In addition to their automotive and industrial applications, oxygen sensors also play a crucial role in medical settings, particularly in monitoring patients with respiratory conditions. These sensors can detect changes in the oxygen concentration in the blood, providing doctors with valuable information about a patient’s respiratory health. This enables healthcare professionals to make informed decisions regarding treatment and ensure the well-being of their patients.

Overall, oxygen sensors are indispensable components in various sectors, aiding in optimizing engine performance, reducing emissions, and promoting respiratory health in medical settings. Their continued development and improvement contribute to a cleaner and healthier environment while enhancing the efficiency of combustion processes.

Types of Oxygen Sensors

There are various types of oxygen sensors that serve different purposes in different applications. Let’s take a closer look at each type and their respective functionalities.

Firstly, we have Zirconia Oxygen Sensors, which are commonly found in automotive applications. These sensors work by comparing the oxygen concentration in the exhaust gas to that of a reference air sample. Zirconia sensors are known for their high accuracy and sensitivity, enabling them to detect even slight changes in oxygen levels. This makes them well-suited for use in emission control systems, where precise monitoring is essential.

Next, we have Titania Oxygen Sensors, which are typically employed in industrial settings to monitor oxygen levels in furnaces and boilers. These sensors operate by measuring changes in the electrical conductivity of a titanium dioxide film in response to fluctuations in oxygen concentration. Titania sensors are known for their durability and resilience, making them reliable even in harsh environments.

For modern vehicles equipped with electronic fuel injection systems, Wideband Oxygen Sensors are utilized. These sensors gauge the oxygen concentration in the exhaust gas and transmit a signal to the engine control module (ECM). The ECM then adjusts the air-fuel ratio based on this input, aiming for optimal engine performance. In addition to their role as a ratio sensor, wideband sensors provide highly precise readings compared to their narrowband counterparts. This improved accuracy contributes to better fuel economy and reduced emissions.

Lastly, Narrowband Oxygen Sensors are commonly found in older vehicles featuring carbureted engines. Similar to wideband sensors, they measure the oxygen concentration in the exhaust gas and relay the information to the ECM for air-fuel ratio adjustments. While narrowband sensors offer less precise readings compared to wideband sensors, they still effectively contribute to maintaining proper engine performance in older vehicle models.

Choosing the appropriate type of oxygen sensor depends on the specific application requirements, including the desired accuracy and sensitivity of the measurements. Whether it’s for emission control in automobiles, monitoring oxygen levels in industrial settings, or optimizing engine performance, the right sensor plays a vital role in ensuring efficient and reliable operation.

Oxygen Sensor Wiring Diagram

Understanding the wiring diagram is crucial for properly connecting and troubleshooting the oxygen sensor. It typically consists of various wires that carry signals related to the oxygen levels in the exhaust gases. These signals are essential for the engine control unit (ECU) to adjust the air-fuel mixture and ensure optimal combustion efficiency.

In most cases, the oxygen sensor wiring includes a power supply wire, a ground wire, and one or more signal wires. The power supply wire provides voltage to the sensor, while the ground wire establishes an electrical connection with the vehicle’s chassis. The signal wires are responsible for transmitting the sensor’s readings to the ECU.

The color of these wires may vary, but commonly used colors include black, white, gray, and sometimes blue. However, it is crucial to note that the color coding can differ between manufacturers. Therefore, it is essential to refer to your specific vehicle’s documentation or consult a professional mechanic for accurate information regarding the color codes.

Additionally, modern vehicles may have multiple oxygen sensors located at different points along the exhaust system. These sensors can be classified as upstream or downstream sensors, depending on their location relative to the catalytic converter. The upstream sensors are positioned closer to the engine, while the downstream sensors are located after the catalytic converter. Each sensor’s wiring will have its own unique diagram.

In conclusion, while the general principles of oxygen sensor wiring apply, it is essential to consult the car owner’s manual or seek professional advice to obtain the specific wiring diagram for your vehicle’s make, model, and sensor brand. This information will ensure that you correctly connect and troubleshoot the oxygen sensor, optimizing your vehicle’s emissions control system and overall performance.

Heated Oxygen Sensor Wiring Diagram

When it comes to the heated oxygen sensor wiring diagram, it’s important to understand how this crucial component operates in a vehicle. The oxygen sensor itself does not initially provide a signal voltage to the car’s computer until it reaches a certain temperature. To achieve this, a heater is incorporated into the emissions sensor. In fact, most cars equipped with OBD II (On-Board Diagnostics II) systems come with a heated oxygen sensor.

The heated oxygen sensor is designed with an internal heater circuit that rapidly warms up the sensor to its operating temperature. This heating element is connected through a separate wiring circuit, typically consisting of two wires. However, it’s worth noting that some oxygen or emission sensors equipped with heaters may have three or four wires instead. These additional wires serve specific purposes and contribute to the overall functionality of the sensor.

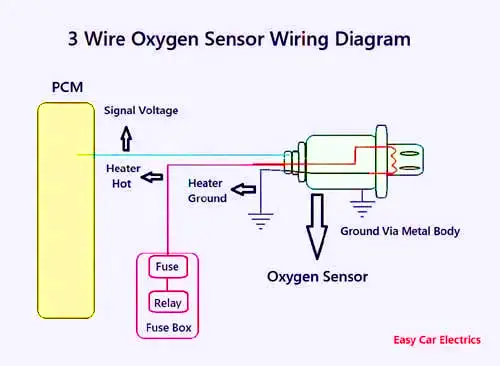

Now, let’s delve into the two common wiring schematics for heated oxygen sensors: the three-wire and four-wire configurations.

3 Wire Oxygen Sensor Wiring Schematic:

In a three-wire setup, the heated oxygen sensor comprises three primary wires. One wire is responsible for providing power to the heater element, which allows it to reach the required operating temperature quickly. Another wire connects to the sensor’s signal output, transmitting the voltage signal to the car’s computer for processing. The third wire serves as a ground connection, completing the electrical circuit.

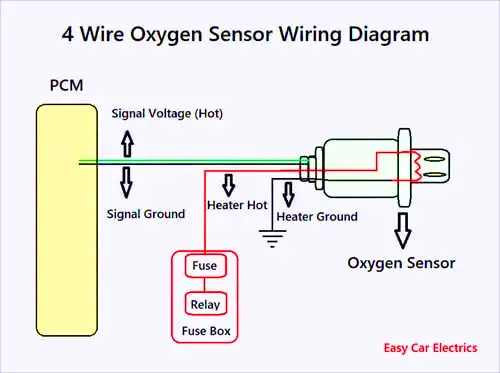

4 Wire Oxygen Sensor Wiring Schematic:

When it comes to the four-wire configuration, an additional wire is included, expanding the capabilities of the oxygen sensor. Alongside the wires responsible for power, signal, and ground, the fourth wire is typically used as a reference voltage wire. This reference voltage wire provides a stable voltage reference point for the oxygen sensor, aiding in accurate signal measurement and interpretation.

Understanding these wiring schematics is crucial for proper installation, troubleshooting, and maintenance of heated oxygen sensors in vehicles. It enables mechanics and automotive enthusiasts to identify and address any issues that may arise with these vital components, ensuring optimal engine performance and efficient emissions control.

By comprehending the intricate workings of the heated oxygen sensor and its associated wiring, individuals can gain a deeper understanding of their vehicle’s emission control system and make informed decisions regarding repairs and upgrades.

3 Wire O2 Sensor Wiring Diagram

Let’s improve and expand upon the information about a three-wire emissions sensor:

A three-wire emissions sensor is a crucial component in a vehicle’s emission control system. It plays a vital role in measuring the oxygen content in the exhaust gases and relaying this information to the Powertrain Control Module (PCM), also known as the car computer. This sensor utilizes three wires to perform its functions effectively.

The first wire is responsible for transmitting the voltage signal generated by the sensor’s sensing element to the PCM. This voltage signal provides valuable data to the car computer, allowing it to make necessary adjustments to the air-fuel mixture for optimal engine performance and emissions control.

The remaining two wires are dedicated to the sensor’s heater circuit. One of these wires connects to the fuse and relays located in the fuse box, providing the necessary power supply to the sensor’s heater element. The heater element helps to maintain a specific temperature range required for accurate sensor operation, especially during cold start conditions when the sensor needs to reach its operating temperature quickly.

The second wire in the heater circuit is grounded to the vehicle’s chassis. This grounding connection ensures stability and safety in the electrical system of the sensor. Additionally, the sensing element of the three-wire oxygen sensor is typically grounded through a metal body that is in direct contact with the exhaust manifold pipe. This grounding method helps to establish a reliable electrical reference point for accurate measurement of the oxygen levels in the exhaust gases.

The three-wire configuration of the emissions sensor allows for efficient operation and precise communication between the sensor and the car computer. By providing both the voltage signal wire for data transmission and the heater circuit for temperature control, this sensor ensures reliable and accurate monitoring of the oxygen content in the exhaust gases, aiding in maintaining optimal engine performance and reducing harmful emissions.

Remember to always consult the vehicle’s specific documentation or seek professional assistance when dealing with sensor installation, troubleshooting, or any electrical system modifications.

4 Wire O2 Sensor Wiring Diagram

The sensing element wires connect to the Powertrain Control Module (PCM), where one wire serves as the signal ground and the second wire carries the signal voltage. In this context, the sensor signal refers to the electric potential transmitted by the air-fuel ratio sensor to the PCM.

The remaining two wires are associated with the heater circuit, namely the hot wire and the earth wire. The heater circuit’s earth wire is typically grounded somewhere in the car’s chassis, while the heater cables are connected to the fuse and relays in the fusebox. Due to the high current consumption of sensor heaters, a relay and a fuse are commonly used to supply battery voltage.

It’s important to note that the control of the heater circuit for the emissions sensor varies depending on the car manufacturer. Some vehicles have the PCM or Engine Control Module (ECM) directly controlling the earth wire of the heater circuit. In these cases, the earth wire is connected to the PCM. On the other hand, certain car manufacturers control the heater circuit using the power wire, where the hot wire is connected to the PCM.

In some instances, the heater circuit is controlled by a relay, with the relay itself being controlled by the PCM. This means that the relay’s earth wire connects to the PCM. The purpose of controlling the heater circuit through the PCM or ECM is to monitor for any open or short circuits in the circuit by receiving feedback.

Additional Information: In most vehicles, the PCM turns off the heater circuit when the ignition switch is ON and the engine is OFF. This is done to prolong the life of the sensor. Furthermore, in certain cars, the heater circuit is disabled when an OBD II code is present.

Additional Information: Compared to a three-wire emissions sensor, a four-wire oxygen sensor offers a better experience. This is because a four-wire oxygen sensor has a dedicated ground wire, eliminating the reliance on the emission manifold as a ground.

Non-Heated Oxygen Sensor Wiring Diagram

When a car is first started, the emissions or oxygen sensor doesn’t generate any voltage until it reaches a certain temperature. This means that non-heated oxygen sensors require the presence of emission gases to heat up and reach their optimal operating temperature.

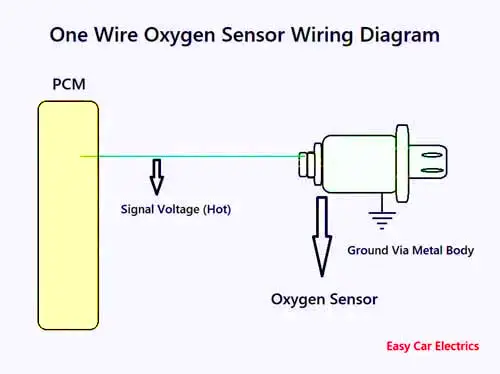

Typically, a sensor without a heater core is equipped with either one or two wires that connect to the Engine Control Unit (ECU). Let’s take a closer look at the wiring schematics for both the one-wire and two-wire non-heated emissions sensors.

The one-wire oxygen sensor utilizes a single wire to transmit data between the sensor and the ECU. This wire serves the purpose of both sending the oxygen sensor’s output signal and providing a ground connection. It’s a relatively simple setup that allows the sensor to communicate its readings to the ECU.

On the other hand, the two-wire oxygen sensor employs an additional wire in comparison to the one-wire variant. One of the wires is responsible for transmitting the oxygen sensor’s output signal to the ECU, while the second wire serves as a dedicated ground connection. This design enables more accurate readings and ensures the sensor’s reliable operation.

It’s important to note that these non-heated oxygen sensors rely on the gases emitted by the engine during its operation to reach their required operating temperature. Once heated, the sensors become fully functional and can provide valuable information to the vehicle’s engine management system, allowing for efficient fuel combustion and reduced emissions.

In modern vehicles, heated oxygen sensors have become more prevalent, as they can reach their optimal operating temperature faster and provide more precise readings from the moment the engine starts. Nevertheless, non-heated oxygen sensors are still found in certain older car models or in specific applications where their characteristics are better suited.

Overall, understanding the wiring and functioning of non-heated oxygen sensors helps us grasp the importance of these components in regulating a car’s emissions and optimizing its performance.

One Wire Oxygen Sensor Wiring Diagram

Let me rephrase and enhance the given text while adding more information:

An oxygen sensor with a single wire refers to a type of sensor that utilizes one signal wire to transmit the sensor voltage to the automotive computer. These sensors are typically grounded through the metal body of the sensor, which is connected to the exhaust manifold pipe.

Oxygen sensors play a crucial role in monitoring the oxygen levels in the exhaust gases of a vehicle. By measuring the amount of oxygen present, they provide vital information for the proper functioning of the engine’s fuel injection system. The one-wire design simplifies the installation process, as it requires only a single wire connection to the vehicle’s computer.

When the engine is running, the one-wire oxygen sensor generates a voltage signal based on the oxygen content in the exhaust stream. This voltage signal is then sent to the automotive computer, allowing it to make adjustments to the air-fuel mixture for optimal engine performance.

It’s important to note that one-wire oxygen sensors may have limitations compared to their counterparts with multiple wires. The single wire design means that the sensor cannot provide real-time data on the oxygen sensor heater circuit. This circuit is responsible for quickly bringing the sensor to its operating temperature for accurate readings. However, despite this limitation, one-wire oxygen sensors continue to be widely used due to their simplicity and cost-effectiveness.

In summary, a one-wire oxygen sensor is a type of sensor that utilizes a single wire to transmit the voltage signal to the automotive computer. It is grounded through the sensor’s metal body, which is connected to the exhaust manifold pipe. These sensors are essential for monitoring the oxygen levels in the exhaust gases, allowing the vehicle’s computer to make necessary adjustments for optimal engine performance. While they may have limitations compared to sensors with multiple wires, their simplicity and affordability make them a popular choice in the automotive industry.

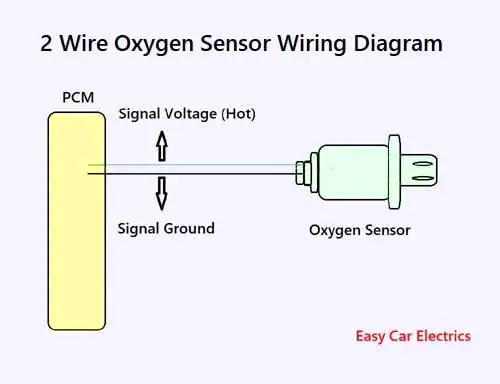

2 Wire O2 Sensor Wiring Diagram

The two-wire oxygen sensor, commonly known as O2 sensor, plays a crucial role in the functioning of an automotive system. It consists of two essential wires: the signal voltage wire and the earth wire.

The signal voltage wire serves as the communication link between the O2 sensor and the automotive computer. This wire allows the emissions sensor to transmit voltage readings to the computer, providing valuable information about the oxygen levels in the exhaust gases. By analyzing these readings, the computer can make adjustments to optimize the engine’s fuel-air mixture, leading to improved performance and reduced emissions.

The second wire, also referred to as the earth wire, is responsible for completing the electrical circuit between the O2 sensor and the automotive computer’s Powertrain Control Module (PCM). This wire ensures that the sensor’s electrical signals can be properly transmitted and interpreted by the computer. The PCM relies on the earth wire to ground the sensor and provide a reference point for voltage measurements.

In addition to these two wires, it’s important to note that modern O2 sensors often come equipped with additional connections. For instance, some sensors feature a heater circuit wire that supplies power to an internal heating element. This heating element allows the sensor to reach operating temperature quickly, improving its accuracy and responsiveness, especially during cold starts.

Furthermore, advancements in O2 sensor technology have led to the development of wideband sensors. Unlike traditional narrowband sensors that primarily monitor the air-fuel ratio around the stoichiometric point, wideband sensors can measure a broader range of oxygen concentrations. These sensors feature multiple wires that facilitate more precise readings, enabling the automotive computer to finely tune the fuel injection and ignition timing for optimal performance and efficiency.

In summary, the two-wire oxygen sensor is a critical component in the automotive system, with the signal voltage wire transmitting oxygen level data to the computer and the earth wire ensuring proper grounding and electrical connectivity. By leveraging this information, the computer can make real-time adjustments to enhance engine performance and minimize harmful emissions. The continuous evolution of O2 sensor technology, including the emergence of wideband sensors, has further improved the accuracy and functionality of these essential automotive devices

Conclusion

Oxygen sensors are essential components that greatly contribute to the efficient functioning of modern engine management systems. These sensors come in four different types: 1-wire, 2-wire, 3-wire, and 4-wire, each characterized by its own distinct wiring schematic. By familiarizing yourself with these diagrams, you gain the ability to diagnose and resolve potential problems related to your engine’s emissions sensor. Whether you’re an experienced mechanic or a skilled car technician, possessing a deep understanding of emissions sensors will prove invaluable in maintaining the optimal performance of your engine.

In addition to their primary function of monitoring oxygen levels in the exhaust gases, oxygen sensors also play a vital role in optimizing fuel efficiency and reducing harmful emissions. The information provided by these sensors allows the engine control unit (ECU) to make real-time adjustments to the air-fuel mixture, ensuring the combustion process is as efficient as possible.

The 1-wire oxygen sensor is the simplest type, consisting of just a single wire that serves both the sensing and heating functions. This design, although less accurate compared to other types, is commonly found in older vehicles. The 2-wire sensor introduces a separate wire for heating the sensor element, improving its response time and accuracy.

Moving on to the more advanced types, the 3-wire oxygen sensor employs two dedicated sensing wires: one for the oxygen signal and another for the sensor’s heating element. This configuration provides enhanced precision and allows for faster response to changes in the exhaust gas composition.

The 4-wire oxygen sensor represents the most sophisticated design, with two additional wires dedicated to a built-in heater control circuit. This circuit ensures precise control of the sensor’s operating temperature, allowing it to reach its optimal working conditions quickly. The 4-wire sensors are commonly used in newer vehicles and offer the highest level of accuracy and responsiveness.

Understanding the specific wiring schematic for each type of oxygen sensor enables you to troubleshoot and address potential issues effectively. By analyzing the sensor’s voltage output, you can determine if it’s functioning correctly or if it requires replacement. Faulty oxygen sensors can lead to decreased fuel efficiency, increased emissions, and even damage to other engine components.

It is worth noting that oxygen sensors have a finite lifespan and will eventually require replacement, typically after around 60,000 to 100,000 miles of driving. Regular maintenance and inspection are essential to ensure optimal sensor performance and overall engine health.

In summary, a comprehensive knowledge of oxygen sensors, including their different types and wiring schematics, is crucial for mechanics and car technicians. This understanding empowers you to diagnose, resolve, and prevent issues related to emissions sensors, ultimately helping to maintain the smooth operation of your engine while minimizing environmental impact.

Frequently Asked Questions (FAQs)

Frequently Asked Questions (FAQs)

What are the white wires on an oxygen sensor?

The color of the wiring on an oxygen sensor can vary depending on the make and model of the vehicle. Different manufacturers may use different wire colors for specific purposes. Typically, the white wires on an oxygen sensor are dedicated to the heater function. The heater is not constantly powered; it only activates when the sensor’s temperature is too low to ensure accurate readings. The oxygen sensor measures the amount of oxygen in the exhaust gases, and if there is an insufficient oxygen level, it indicates a rich fuel mixture that needs adjustment.

What happens if I unplug my O2 sensor?

If you unplug your O2 sensor, it will lose its ability to measure the oxygen content in the exhaust gases. This can lead to the engine running either too lean or too rich, depending on the circumstances. When the engine runs too lean, it may lack power and potentially overheat. On the other hand, if it runs too rich, it will consume more fuel than necessary and may produce excessive emissions.

Can I run my car without an oxygen sensor?

Technically, you can still drive your car without an oxygen sensor, but its efficiency will be compromised. Without the sensor, the engine will operate in a rough and sluggish manner. Vehicles are designed to run on a specific air-to-fuel mixture, ideally at a ratio of 14.7 parts air to 1 part fuel. The oxygen sensor, also known as the lambda sensor, continuously monitors the oxygen levels in the exhaust gases and adjusts the air-fuel mixture accordingly. Without an oxygen sensor, the engine’s efficiency will decrease, and the car may experience increased wear and tear.

How can I troubleshoot a faulty front oxygen sensor on my Toyota? Should I check the wiring harness or the sensor connector, and how do I use a multimeter to determine if the sensor is bad?

When troubleshooting a faulty front oxygen sensor on a Toyota, it’s crucial to inspect both the wiring harness and the sensor connector. A malfunctioning sensor can cause fuel trim and diagnostic trouble code (DTC) issues, so proper diagnosis is important. To determine if the sensor is faulty using a multimeter, you can follow these steps:

- Begin by disconnecting the sensor’s connection and setting your multimeter to the resistance setting.

- Measure the resistance between the two heater wires of the oxygen sensor.

- At room temperature, the resistance should typically range between 10 and 20 ohms.

By checking the resistance, you can assess whether the sensor’s heater element is within the expected range. If the resistance is significantly outside the specified range, it indicates a faulty sensor that may need replacement or further inspection.

Remember to consult your vehicle’s specific repair manual or seek professional assistance for detailed guidance tailored to your Toyota model.

RACEXT QUALITY GUARANTEE

RACEXT QUALITY GUARANTEE

Every Racext performance product is thoroughly tested and guaranteed, even if it doesn’t feature a visible logo. Due to production and logistical reasons, some products may not carry the Racext branding directly on the item.

However, rest assured that all our products undergo rigorous quality checks and are backed by Racext’s commitment to performance and reliability.

EXCLUSIVE MANUFACTURING AND DISTRIBUTION

EXCLUSIVE MANUFACTURING AND DISTRIBUTION

Our trusted partners manufacture each product according to our specific technical requirements, ensuring that every item meets Racext’s high standards. All our products are exclusively sold by Racext and are not distributed by other companies.

Even though some of our partners commercialize similar products for cars, these items are not compatible with motorcycles due to distinct resistance and amperage requirements.

PRECISION-CALIBRATED CHIP TUNING DEVICES

PRECISION-CALIBRATED CHIP TUNING DEVICES

When it comes to our chip tuning devices, the resistance is precisely calibrated to be perfectly adapted to different vehicles, such as motorcycles. This ensures optimal performance, compatibility, and a smooth ride without any risk to your vehicle’s electronic systems.

Racext chip tuning devices are specially designed to meet the unique demands of motorcycle performance systems, guaranteeing that your bike runs efficiently and reliably.

This product is not certified, approved or homologated for use on public roads or highways in any country. It is intended solely for off-road use, closed-circuit racing, sports competition, or private testing purposes. Installation and use of this product on vehicles driven on public streets is strictly prohibited and may violate traffic laws, emissions regulations, or technical inspection requirements.

By purchasing this product, the customer acknowledges and agrees that:

- The product is sold “as is” for motorsport or off-road use only.

- It is not street-legal and must not be used on public roads under any circumstance.

- The seller (Racext) assumes no responsibility for any improper, illegal or unintended use of this product.

- The customer is solely responsible for verifying whether the installation and use of this product comply with local laws and regulations.

- This product may affect vehicle warranty and insurance if used outside of permitted contexts.

This notice applies regardless of the country in which the product is purchased or shipped, including (but not limited to) the United States, Canada, the European Union, the United Kingdom, Australia and New Zealand.

By proceeding with the purchase, you confirm that you have read, understood and accepted this disclaimer, and release the seller from any liability arising from misuse or unauthorized application of the product.

QUALITY STANDARDS ACROSS ALL PRODUCTS

QUALITY STANDARDS ACROSS ALL PRODUCTS

This high standard of exclusive design, manufacturing, and compatibility applies to all Racext products available for purchase. Every item in our catalog is crafted with the same dedication to performance, safety, and quality.

Disclaimer

TRANSPARENT SHIPPING POLICY

Cutoff time 22:00 (GMT+01:00) Central European Standard Time (Amsterdam)

Order Processing Time 1-3 days (Mon-Fri)

Delivery time 3-6 days (Monday-Friday)

Our orders are free of shipping costs.

We use the following shipping couriers:

- PostNL

- Dhl

- UPS

- DPD

- Cainiao

The customer will receive the tracking information in 1-3 days directly in his email. Please contact us if you have not received the email or check your spam emails

LEGAL DISCLAIMER: PRODUCTS INTENDED EXCLUSIVELY FOR SPORTING AND COMPETITIVE USE

Important: Before proceeding with the purchase or use of our sport exhausts, please read the following notice carefully.

The products sold through this website are intended exclusively for sporting and competitive use. This means they have been designed and manufactured to be used in controlled environments, such as closed circuits or areas designated for sporting competitions, where emission and noise regulations may differ from those applied on public roads.

Public Road Use Not Allowed: It is emphasized that the installation and use of these devices on vehicles intended for circulation on public roads may not be permitted under the laws of your reference country regarding emission and noise regulation, as they are not designed for road use but for sporting use.

Buyer’s Responsibility: It is the buyer’s responsibility to ensure that the use of the purchased products complies with all applicable laws and regulations. The buyer assumes all legal liabilities for any non-compliant use of the products, including the installation and operation of such devices on unauthorized vehicles or in ways that violate applicable laws.

By continuing with the purchase, the buyer acknowledges and agrees that the use of the products is limited to sporting and competitive contexts as defined above and assumes full responsibility for any legal consequences arising from improper use of the products.

Oxygen Sensor: 1, 2, 3, 4 Wire O2 Sensor Wiring Diagram

Compatibility:

It is the responsibility of the customer to ensure that the product is compatible with their vehicle. We recommend consulting with a professional mechanic before purchasing to confirm compatibility. Racext is not responsible for any issues that may arise from the use of our products, including but not limited to damage to the vehicle or personal injury.

Warranty:

All of our products come with a 2-year warranty in accordance with international standards. If you experience any issues with your product within the warranty period, please contact us for assistance. The warranty does not cover damages caused by improper installation, misuse, or external factors such as accidents or natural disasters.

Returns

ABOUT US

ADDRESS: Creative Tower – Hamad Bin Abdulla Road – Office 4201 – Fujairah – U.A.E.

E-mail : info@Racext.com

Contact form : Get in touch

Phone : +971 58 859 1706

Company name : Digitanow International group FZe

Company Number : AE18048/2020

Tax registration number: AE18048 2020

Customer service : Monday to Friday from 9 a.m. to 8 p.m.

Terms and Conditions

This website provides only the product with well-indicated codes and specifications. Please rely on an experienced workshop for the installation and choice of the product. We do not assume any responsibility for errors in choice, installation, or programming of the devices.

*The price is intended for a single product

*Days are always working days

All guides on this website are for illustrative purposes only. For many products, the use of special tools may be necessary. We always recommend seeking the advice of a specialized repair center for the selection and installation or programming of products purchased anywhere. We do not assume any responsibility for damage to property or persons, or user errors in the application of a guide on this website or for any other occurrence.

Product is not original but fully interchangeable with it

All rights reserved. All trade names and logos are registered trademarks of the respective manufacturers indicated

The trademarks mentioned on this site are the exclusive property of the automotive companies and are used here exclusively to facilitate the search for vehicles by our customers. We do not assume any responsibility for damages to property or persons, or user errors in the application of a guide on this website or for any other occurrence.

Secure Payments

When making purchases on our website, you can be confident that your transaction is secure. All financial transactions are processed on the secure and certified servers of PayPal or Stripe. These platforms allow us to accept payments from all VISA, VISA ELECTRON, MAESTRO, POSTEPAY, AMERICAN EXPRESS, AURA, and DISCOVER credit cards.

Quality Guarantee

Choose safety, savings, and professionalism by choosing us. We offer top-level customer support that will never leave you alone during the pre- and post-purchase phases. We offer top-quality products and intelligent, secure savings. Don’t trust inexperienced sellers.

NOTE: In the event that the product is not available in stock, we reserve the right to issue a full and immediate refund.

Get 10% OFF and

Get 10% OFF and  FREE SHIPPING on any order with code: Bike10

FREE SHIPPING on any order with code: Bike10

Arabic

Arabic Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch English

English French

French German

German Greek

Greek Italian

Italian Japanese

Japanese Maltese

Maltese Norwegian

Norwegian Polish

Polish Portuguese

Portuguese Romanian

Romanian Serbian

Serbian Slovenian

Slovenian Spanish

Spanish Swedish

Swedish Need help?

Need help?