Car Magazine

How to push back brake piston without tool

How to push back brake piston without tool – on our site you will find the best spare parts and accessories for cars and motorcycles

SELECT YOUR VEHICLE'S BRAND AND MODEL TO FIND ALL COMPATIBLE PRODUCTS ON RACEXT.

✅ Choose free delivery to save more

How to push back brake piston without tool

Before purchasing our products, it is advisable to read the product sheet. If in doubt, do not hesitate to contact us, we will be happy to help you choose the product that best suits your needs

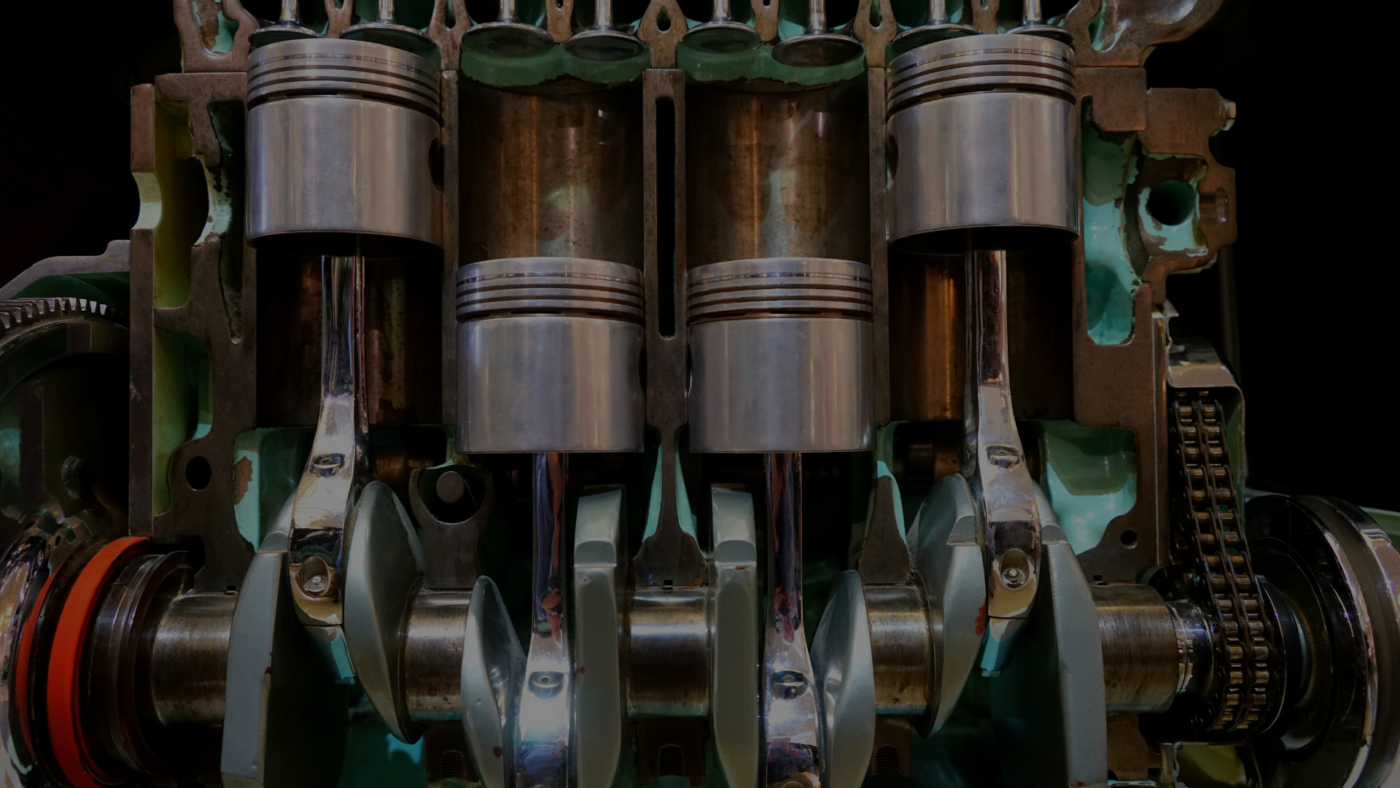

If you are looking for high quality products for your car or motorbike, look no further. We are sure you will find the perfect product for you at Racext. Do not hesitate to contact us with any questions or requests. We are here to help you make your vehicle perfect.In order to effectively push back the brake piston without a specialized tool, it is essential to have a thorough understanding of the brake piston and its function. The brake piston is a crucial component of the brake caliper assembly, responsible for applying pressure to the brake pads, which in turn creates friction against the rotor to slow down or stop the vehicle. It works in conjunction with the brake master cylinder and brake fluid to facilitate the hydraulic braking system.

The brake piston is typically made of durable materials such as steel or aluminum, designed to withstand high temperatures and intense braking forces. Its primary function is to translate the hydraulic pressure generated by the brake pedal into mechanical force, pressing the brake pads against the rotor. As a result, friction is created, generating the necessary stopping power.

Understanding the brake piston’s function is vital when attempting to push it back without a dedicated tool. By comprehending its role within the braking system, one can adopt alternative techniques or manual methods to safely and effectively retract the piston. This knowledge enables mechanics and enthusiasts to perform brake maintenance or repairs even in situations where a specialized tool is not available.

1.2 Importance of Proper Brake Maintenance and Repair

Proper brake maintenance and repair play a crucial role in ensuring the safety and optimal performance of a vehicle’s braking system. It is essential for every mechanic and enthusiast to understand the importance of regular brake maintenance and address any issues promptly. Neglecting brake maintenance can lead to various problems, including decreased braking efficiency, excessive wear on brake components, and even brake failure.

By maintaining the brakes in good condition, drivers can have confidence in their vehicle’s ability to stop effectively and safely in different driving conditions. Regular inspection and servicing of the brake system, including the brake pads, rotors, calipers, and brake fluid, help identify any signs of wear, damage, or malfunction. Timely repairs or replacements can prevent further damage and ensure the brakes operate optimally.

Proper brake maintenance also extends the lifespan of brake components, reducing the frequency of replacements and associated costs. Additionally, well-maintained brakes contribute to fuel efficiency since a properly functioning braking system minimizes unnecessary drag on the vehicle’s drivetrain.

Overall, understanding the significance of proper brake maintenance and repair emphasizes the importance of effectively pushing back the brake piston without a specialized tool. By adopting alternative methods or manual techniques to retract the piston, mechanics and enthusiasts can ensure the integrity and reliability of the braking system, promoting safety on the road.

1.3 Challenges of Pushing Back Brake Piston without a Too

Pushing back the brake piston without a specialized tool can present several challenges for mechanics and enthusiasts. The primary difficulty arises from the design of modern brake systems, which often incorporate pistons that are not easily retractable by hand. Unlike older brake systems with straightforward piston retraction mechanisms, newer vehicles often utilize pistons that require rotational or simultaneous inward pressure to retract.

Without a dedicated brake piston tool, mechanics must rely on alternative methods that may be more time-consuming and labor-intensive. These methods may involve using pliers, C-clamps, or even improvised tools to exert force on the piston and push it back into its housing. However, these improvised methods can be less precise and increase the risk of damaging the piston or surrounding brake components.

Another challenge is ensuring the even retraction of multiple pistons found in some brake systems, such as those used in multi-piston calipers. Each piston must be retracted simultaneously and evenly to avoid uneven brake pad wear and potential braking imbalances. Achieving this level of precision without a dedicated tool can be demanding and may require extra effort and attention.

Furthermore, certain brake systems incorporate additional features, such as parking brake mechanisms or electronic systems, which further complicate the piston retraction process. These additional components may require specific procedures or tools to properly retract the piston without causing damage or triggering warning lights in the vehicle’s dashboard.

Overcoming these challenges requires patience, skill, and a thorough understanding of the specific brake system being worked on. Mechanics and enthusiasts should exercise caution and refer to manufacturer guidelines or seek professional advice when attempting to push back the brake piston without a specialized tool. By being aware of the challenges involved, individuals can approach the task with the necessary knowledge and take appropriate precautions to ensure a successful and safe brake maintenance procedure.

Chapter 2: Preparation for Pushing Back Brake Piston

2.1 Gathering the Necessary Tools and Materials

Before attempting to push back the brake piston, it is crucial to gather the necessary tools and materials to ensure a smooth and efficient process. As a professional mechanic, it is essential to have a well-equipped toolbox that includes a set of wrenches, pliers, and screwdrivers of various sizes. Additionally, specific brake system tools, such as brake piston retracting tools, may be required depending on the vehicle’s make and model.

In addition to tools, it is vital to have the appropriate materials on hand. This includes a brake system cleaner to remove any dirt, debris, or brake fluid residue from the brake components. Brake lubricant or high-temperature grease should also be available to ensure smooth movement and prevent corrosion of the brake caliper and piston.

It is recommended to have a brake bleeding kit or a suitable container to collect and dispose of the brake fluid during the process. Safety should always be a priority, so wearing protective gloves and safety glasses is highly recommended to avoid contact with brake fluid or any other hazardous substances.

Furthermore, having the vehicle’s service manual or repair guide specific to the make and model is invaluable. This resource will provide essential information about the brake system, including the recommended procedures for pushing back the brake piston without a specialized tool. It may also include any specific precautions or warnings related to the particular vehicle’s brake system.

By gathering the necessary tools and materials beforehand, mechanics can work efficiently and with confidence during the brake piston retraction process. Proper preparation minimizes the risk of complications and helps ensure the safety and effectiveness of the brake maintenance or repair task.

2.2 Ensuring Safety Measures and Personal Protective Equipment (PPE)

When preparing for the task of pushing back the brake piston, it is essential to prioritize safety by implementing proper safety measures and utilizing personal protective equipment (PPE). As a professional mechanic, it is imperative to be proactive in ensuring a safe working environment and minimizing the risk of accidents or injuries.

First and foremost, it is crucial to work in a well-ventilated area to avoid inhaling harmful fumes or gases. If the task is performed indoors, ensure adequate ventilation through open doors, windows, or the use of exhaust fans. If working in a garage or enclosed space, consider using a portable fan or wearing a respirator if necessary.

Wearing appropriate personal protective equipment is vital to protect oneself from potential hazards. Safety glasses or goggles should be worn to shield the eyes from flying debris, brake fluid splashes, or any other foreign objects. In addition, wearing gloves made of durable and chemical-resistant materials will protect the hands from cuts, burns, and exposure to brake fluid or other harsh chemicals.

Furthermore, it is essential to follow proper ergonomic practices to prevent strains, muscle injuries, or fatigue. Maintaining a comfortable working posture, using proper lifting techniques, and taking regular breaks can help reduce the risk of work-related injuries.

Before starting the task, it is recommended to secure the vehicle in a stable position using wheel chocks or blocks and engage the parking brake to prevent any accidental movement. This will provide a stable and secure working environment.

Lastly, it is crucial to familiarize oneself with the vehicle’s specific safety procedures and precautions outlined in the service manual or repair guide. Understanding any potential risks associated with the brake system and following the manufacturer’s recommendations will contribute to a safe working environment.

By ensuring safety measures and utilizing proper personal protective equipment, professional mechanics can effectively mitigate risks and maintain a secure working environment throughout the process of pushing back the brake piston. Safety should always be the top priority to protect oneself and deliver reliable and efficient brake system maintenance or repair services.

2.3 Positioning the Vehicle and Removing Wheel Assembly

Properly positioning the vehicle and removing the wheel assembly are essential steps in preparing to push back the brake piston. As a professional mechanic, attention to detail and precision are crucial to ensure a smooth and efficient process.

To begin, park the vehicle on a flat and level surface. Engage the parking brake and place wheel chocks or blocks behind the wheels to prevent any unintended movement. This will provide stability and minimize the risk of accidents during the procedure.

Next, locate the designated jacking points on the vehicle. These points are typically indicated in the owner’s manual or can be identified by examining the chassis structure. Position a hydraulic jack or a suitable lifting device under the specified jacking point and slowly raise the vehicle until the wheel being worked on is off the ground. Secure the vehicle with jack stands placed under the recommended support points to ensure stability and prevent the vehicle from falling.

With the vehicle properly supported, use a lug wrench or a suitable tool to loosen the lug nuts on the wheel that needs to be removed. Loosen the lug nuts in a diagonal pattern to evenly release the tension. Once the lug nuts are loosened, remove them completely and carefully slide the wheel off the hub assembly.

It is important to handle the wheel assembly with care to avoid any damage or injury. Place the removed wheel in a safe location away from the work area, ensuring it is secured to prevent rolling.

At this point, the wheel assembly has been successfully removed, providing clear access to the brake caliper and piston. This accessibility is crucial for the subsequent steps of pushing back the brake piston without a specialized tool.

By meticulously positioning the vehicle and safely removing the wheel assembly, professional mechanics can establish a solid foundation for effectively completing the task of pushing back the brake piston. Attention to detail, adherence to safety procedures, and utilizing appropriate equipment are key factors in ensuring a successful and safe brake maintenance or repair process.

Chapter 3: Manual Methods for Pushing Back Brake Piston

3.1 Using a C-Clamp and Wooden Block Technique

Using a C-clamp and wooden block technique is a reliable and effective manual method for pushing back the brake piston. As a professional mechanic, it is important to be familiar with various techniques that can be employed when specialized tools are not readily available.

To begin, gather a C-clamp, a wooden block or a piece of sturdy material, and a pair of pliers. The C-clamp should have sufficient opening width to accommodate the brake caliper and piston. The wooden block should be thick enough to distribute pressure evenly across the piston surface without causing damage.

First, locate the brake caliper housing and identify the piston that needs to be pushed back. Carefully inspect the caliper to ensure there are no signs of damage or excessive wear that may affect its functionality.

Next, position the wooden block against the piston, ensuring it is aligned properly and covers the entire surface. This will act as a buffer between the C-clamp and the piston to prevent direct contact and potential damage.

Place the C-clamp over the wooden block, aligning it with the piston. Slowly tighten the C-clamp by turning the screw or handle clockwise. As the clamp tightens, the piston will gradually retract into the caliper housing. It is important to apply pressure evenly to avoid any tilting or misalignment of the piston.

As the piston retracts, periodically check the brake fluid reservoir to ensure it does not overflow. If necessary, remove some fluid using a clean syringe or suction device to maintain the appropriate level.

Continue tightening the C-clamp until the piston is fully retracted into the caliper housing. Once the piston is in the desired position, carefully release the pressure on the C-clamp by turning the screw or handle counterclockwise.

Before proceeding with further brake maintenance or assembly, visually inspect the caliper and piston to confirm that the retraction was successful and that there are no signs of damage or misalignment.

The C-clamp and wooden block technique provides a practical and accessible method for pushing back the brake piston manually. However, it is important to exercise caution and follow proper procedures to ensure the safety and integrity of the brake system. Professional mechanics should always prioritize precision and meticulousness when performing brake maintenance or repair tasks.

3.2 Leveraging a Screwdriver and Pry Bar Method

Leveraging a screwdriver and pry bar method is another manual approach that can be used to push back the brake piston when specialized tools are not available. As a professional mechanic, it is essential to have a range of techniques at your disposal to handle various situations effectively.

To begin, gather a flathead screwdriver, a sturdy pry bar, and a pair of pliers. Inspect the brake caliper and piston to ensure they are in good condition and free from any damage or excessive wear.

Position the flathead screwdriver between the brake pad and the brake rotor, carefully wedging it to create leverage. Ensure that the screwdriver is securely positioned to prevent slipping during the process.

Using the pry bar, place one end against the screwdriver and the other end against a stable part of the caliper or caliper bracket. Apply controlled pressure with the pry bar to push against the screwdriver, gradually pushing the piston back into the caliper housing.

Take caution while applying pressure to avoid any damage to the caliper or surrounding components. It is crucial to maintain a steady and even force to prevent tilting or misalignment of the piston.

As the piston retracts, periodically monitor the brake fluid reservoir to prevent overflow. If the fluid level is too high, use a clean syringe or suction device to remove excess fluid.

Continue leveraging the screwdriver and pry bar method until the piston is fully retracted into the caliper housing. Once the desired position is achieved, release the pressure on the screwdriver and pry bar slowly and carefully.

After completing the piston retraction, visually inspect the caliper and piston to ensure proper alignment and no signs of damage. Ensure that the brake pads are correctly positioned and that the caliper is secure.

It is important to note that this manual method requires precision and caution to avoid any unintended consequences. Professional mechanics should exercise care when performing brake maintenance tasks, adhering to proper safety procedures and industry standards.

The screwdriver and pry bar method serves as a practical alternative when specialized tools are not available, providing an effective means of pushing back the brake piston manually. However, it is recommended to utilize dedicated brake piston tools whenever possible for optimal performance and safety.

3.3 Employing the “G-Clamp and Hammer” Technique Chapter 3: Manual Methods for Pushing Back Brake Piston

Employing the “G-Clamp and Hammer” technique is another manual method that can be used to push back the brake piston in the absence of specialized tools. As a professional mechanic, it is important to be resourceful and familiar with a variety of techniques to handle different situations effectively.

To begin, gather a G-clamp, a block of wood or a metal plate, and a rubber mallet or a hammer with a rubberized tip. Inspect the brake caliper and piston to ensure they are in good condition and free from any damage or excessive wear.

Position the block of wood or metal plate on the brake pad, making sure it covers the entire surface of the piston. This will help distribute the force evenly and protect the piston from direct contact with the clamp.

Place the G-clamp over the block of wood or metal plate, aligning it with the piston. Slowly tighten the clamp, applying controlled pressure to push the piston back into the caliper housing.

Be cautious while tightening the clamp to avoid any damage to the caliper or surrounding components. It is important to exert pressure evenly to prevent tilting or misalignment of the piston.

As you tighten the clamp, periodically tap the brake caliper with a rubber mallet or a hammer with a rubberized tip. This helps to loosen any resistance and allows the piston to retract smoothly.

Continue tightening the clamp and tapping the caliper until the piston is fully retracted into the caliper housing. Once the desired position is achieved, release the pressure on the clamp slowly and carefully.

After completing the piston retraction, visually inspect the caliper and piston to ensure proper alignment and no signs of damage. Verify that the brake pads are correctly positioned and that the caliper is securely fastened.

It is important to note that this manual method requires precision and care to avoid unintended consequences. Professional mechanics should exercise caution when performing brake maintenance tasks, adhering to proper safety procedures and industry standards.

The “G-Clamp and Hammer” technique serves as a practical option when specialized tools are not available, providing a means of manually pushing back the brake piston. However, it is recommended to utilize dedicated brake piston tools whenever possible for optimal performance and safety.

Chapter 4: Alternative Techniques for Pushing Back Brake Piston

4.1 Utilizing a Set of Vise Grips and Gently Compressing the Piston

Utilizing a set of vise grips and gently compressing the brake piston is an alternative technique that can be employed to push back the piston when specialized tools are not readily available. As a professional mechanic, it is essential to be adaptable and knowledgeable about various methods to overcome challenging situations effectively.

Start by selecting a suitable pair of vise grips with jaws that can securely grip the brake piston. Inspect the brake caliper and piston for any signs of damage or wear, ensuring they are in good condition before proceeding.

Position the vise grips around the outer edge of the brake piston, ensuring a firm grip without causing any damage. It is crucial to apply even pressure on both sides of the piston to prevent tilting or misalignment.

Slowly and steadily compress the piston by squeezing the vise grips. Take care to exert force gradually, allowing the brake fluid to flow back into the master cylinder. This controlled compression helps retract the piston into the caliper housing.

During the compression process, it is advisable to periodically inspect the caliper and piston to ensure proper alignment and prevent any potential damage. Be cautious not to over-compress the piston, as it may cause brake fluid leakage or affect the performance of the braking system.

Once the piston is fully retracted into the caliper housing, release the pressure on the vise grips slowly and carefully. Verify that the piston is in its correct position and that the brake pads are properly aligned.

After completing the piston compression, conduct a visual inspection of the brake system, ensuring all components are securely fastened and free from any damage. Test the brake pedal to ensure it provides the appropriate resistance and responsiveness.

It is important to note that this alternative technique requires precision and attention to detail to prevent any adverse effects on the braking system. Professional mechanics should exercise caution, adhere to proper safety procedures, and consult manufacturer guidelines whenever possible.

While utilizing specialized tools designed for pushing back brake pistons is recommended, the utilization of vise grips can serve as a practical option in situations where dedicated tools are unavailable. However, it is always advisable to use the appropriate tools and techniques specifically designed for brake maintenance to ensure optimal performance and safety.

4.2 Applying Controlled Pressure with a Pair of Channel Locks

Applying controlled pressure with a pair of channel locks is another alternative technique that can be used to push back the brake piston when specialized tools are not readily available. As a professional mechanic, it is important to have a diverse set of skills and knowledge to handle different situations effectively.

To begin, ensure that the channel locks are in good condition and properly adjusted to securely grip the brake piston. Inspect the brake caliper and piston for any signs of damage or wear, ensuring they are in proper working order before proceeding.

Position the jaws of the channel locks around the outer edge of the brake piston, taking care not to damage the piston or surrounding components. It is crucial to apply even pressure on both sides of the piston to ensure proper retraction without causing any misalignment.

Slowly and steadily apply pressure with the channel locks, compressing the piston back into the caliper housing. This controlled application of force allows the brake fluid to flow back into the master cylinder and retracts the piston.

Throughout the compression process, periodically inspect the caliper and piston to ensure proper alignment and prevent any potential damage. It is important to maintain control and avoid over-compressing the piston, which can lead to brake fluid leakage or affect the overall performance of the braking system.

Once the piston is fully retracted into the caliper housing, release the pressure from the channel locks gradually and carefully. Verify that the piston is in its correct position and that the brake pads are properly aligned.

After completing the piston compression, conduct a thorough inspection of the brake system to ensure all components are securely fastened and free from any damage. Test the brake pedal to ensure it provides the appropriate resistance and responsiveness.

It is crucial to exercise caution and precision when using this alternative technique to push back the brake piston. Adhere to proper safety procedures, avoid excessive force, and consult manufacturer guidelines whenever possible.

While using specialized tools designed for pushing back brake pistons is recommended, employing channel locks can serve as a practical option in situations where dedicated tools are unavailable. However, it is always advisable to use the appropriate tools and techniques specifically designed for brake maintenance to ensure optimal performance and safety.

4.3 Using a Large Adjustable Wrench and Slowly Pushing the Piston

Using a large adjustable wrench and slowly pushing the brake piston is another viable alternative technique for pushing back the brake piston when specialized tools are not readily available. As a professional mechanic, it is essential to be resourceful and adaptable in order to handle various situations effectively.

Before beginning the process, carefully inspect the brake caliper and piston for any signs of damage or wear. Ensure that they are in proper working condition and free from any abnormalities.

Start by selecting a large adjustable wrench that fits securely around the piston. Adjust the wrench jaws to provide a snug fit without causing any damage to the piston or surrounding components.

Position the wrench jaws on the flat surface of the brake piston, making sure to distribute the pressure evenly. It is crucial to apply force gradually and avoid sudden movements that may lead to misalignment or damage.

Using slow and controlled movements, begin pushing the wrench handle towards the caliper housing. This action compresses the brake piston back into its original position, allowing the brake fluid to flow back into the master cylinder.

Throughout the process, regularly check the alignment of the piston and caliper to ensure smooth retraction without any complications. It is important to maintain a steady and controlled motion, taking care not to over-compress the piston.

Once the piston is fully retracted, carefully release the pressure from the wrench, ensuring that the piston remains aligned and properly positioned within the caliper housing.

After completing the piston compression, conduct a thorough inspection of the brake system to verify that all components are securely fastened and undamaged. Test the brake pedal to ensure it provides the appropriate resistance and responsiveness.

It is vital to exercise caution and precision while using this alternative technique. Adhere to proper safety procedures, avoid excessive force, and consult manufacturer guidelines whenever possible.

While using specialized tools designed specifically for pushing back brake pistons is recommended, utilizing a large adjustable wrench can serve as a practical option in situations where dedicated tools are not available. However, it is always advisable to use the appropriate tools and techniques specifically designed for brake maintenance to ensure optimal performance and safety.

Chapter 5: Best Practices and Tips for Pushing Back Brake Piston

5.1 Ensuring Proper Alignment and Stability during the Proces

Ensuring proper alignment and stability during the process of pushing back the brake piston is crucial for maintaining the integrity and functionality of the brake system. As a professional mechanic, it is essential to follow best practices and utilize effective techniques to achieve the desired results.

Before initiating the procedure, it is important to position the vehicle on a level surface and engage the parking brake. This ensures stability and prevents any unintended movement during the process.

Inspect the brake caliper and surrounding components for any signs of damage or corrosion. Ensure that all bolts and fasteners are secure and properly tightened. Any loose or damaged parts should be addressed before proceeding further.

When pushing back the brake piston, it is crucial to apply force evenly and maintain proper alignment. Misalignment can lead to uneven pressure distribution and potential damage to the piston or caliper.

To achieve proper alignment, it is recommended to use a tool specifically designed for the task, such as a piston retraction tool or a brake caliper cube. These tools provide precise alignment and ensure the piston is compressed evenly.

If specialized tools are not available, alternative methods such as using a large adjustable wrench or other manual techniques can be employed. However, it is imperative to exercise caution and take extra care to maintain alignment and stability throughout the process.

Avoid using excessive force or sudden movements when pushing back the brake piston. Applying gradual and controlled pressure allows for a smooth retraction without risking damage to the piston or other brake components.

Throughout the process, regularly inspect the alignment of the piston and caliper. Adjust as necessary to ensure proper positioning and avoid any potential issues with brake pad clearance or rotor contact.

It is also advisable to refer to the vehicle’s manufacturer guidelines or service manual for specific instructions and recommendations pertaining to the brake system. Following the manufacturer’s guidelines ensures compliance with their specifications and maintains the warranty, if applicable.

After successfully pushing back the brake piston, conduct a final inspection to verify proper alignment, stability, and functionality. Check for any leaks, ensure all bolts are securely fastened, and confirm the correct operation of the brake pedal.

By adhering to best practices, utilizing proper alignment techniques, and following manufacturer guidelines, you can confidently and effectively push back the brake piston, ensuring the reliability and performance of the brake system.

5.2 Taking Caution to Prevent Damage to Brake Calipers or Seals

When pushing back the brake piston, it is crucial to take caution to prevent any damage to the brake calipers or seals. As a professional mechanic, ensuring the integrity of these components is essential for the proper functioning of the braking system.

First and foremost, visually inspect the brake calipers and seals for any signs of wear, damage, or leakage. If any issues are detected, it is recommended to replace the calipers or seals before attempting to push back the piston.

During the process, it is important to avoid applying excessive force or using tools that may cause damage. Forceful or abrupt movements can lead to caliper distortion, seal damage, or even piston rupture. Instead, employ gentle and controlled pressure to retract the piston.

To protect the brake calipers and seals, consider using a suitable protective material, such as a rubber pad or a cloth, between the tool and the caliper. This helps to distribute the force evenly and minimizes the risk of direct contact that could cause damage.

When using manual techniques, such as a C-clamp or channel locks, ensure that the tool is positioned correctly to avoid placing pressure on the caliper housing or other sensitive components. The force should be applied directly to the piston to prevent any sideways or uneven pressure.

Additionally, be mindful of the piston’s movement and any resistance encountered during the process. If the piston feels unusually stiff or does not retract smoothly, it may indicate underlying issues, such as corroded caliper slides or seized pistons. In such cases, it is recommended to inspect and address the root cause before proceeding further.

Throughout the procedure, periodically inspect the brake calipers and seals for any signs of damage or leaks. If any abnormalities are detected, stop the process and address the issue before continuing. Ignoring potential damage can compromise the overall safety and performance of the braking system.

By taking caution, employing gentle pressure, and utilizing protective measures, you can minimize the risk of damaging the brake calipers or seals while pushing back the brake piston. This ensures the longevity and reliability of the braking system and contributes to a safe and efficient driving experience.

5.3 Checking Brake Fluid Reservoir and Performing Final Inspections

After successfully pushing back the brake piston, it is crucial to perform final inspections and ensure the proper functioning of the braking system. As a professional mechanic, this step is vital to confirm that the brake calipers, seals, and other components are in good condition and ready for operation.

Begin by checking the brake fluid reservoir. It is essential to verify that the fluid level is within the recommended range. Insufficient brake fluid can lead to poor brake performance, while overfilling can cause fluid leakage or damage to the seals. If necessary, add or remove brake fluid accordingly, following the manufacturer’s specifications.

Next, visually inspect the brake calipers, paying close attention to any signs of leakage, irregular wear patterns, or loose connections. Additionally, check the condition of the brake pads or shoes, ensuring they are properly aligned and have sufficient thickness for safe braking. If any issues are detected, address them promptly by replacing or repairing the affected components.

During the inspection, also examine the brake lines and hoses for any signs of damage, such as cracks, bulges, or leaks. Damaged brake lines can compromise the hydraulic pressure and lead to brake failure, so it is crucial to address any issues immediately.

Furthermore, perform a thorough test of the braking system. Engage the brake pedal several times and evaluate its responsiveness and firmness. Pay attention to any unusual noises, vibrations, or changes in brake performance. If you notice any abnormalities, investigate the cause and make any necessary adjustments or repairs.

Lastly, take the vehicle for a test drive in a controlled environment, such as an empty parking lot or a quiet road. Gradually apply the brakes at different speeds and assess the overall braking performance. Ensure that the vehicle stops smoothly and evenly without any pulling or excessive noise. If any issues persist, further investigation and adjustments may be required.

By checking the brake fluid reservoir, performing final inspections, and conducting a test drive, you can verify the effectiveness and safety of the braking system after pushing back the brake piston. This thorough evaluation ensures that the brakes are in optimal condition, providing reliable stopping power and contributing to a secure driving experience.

🌊 RACEXT QUALITY GUARANTEE

Every Racext performance product is thoroughly tested and guaranteed, even if it doesn’t feature a visible logo. Due to production and logistical reasons, some products may not carry the Racext branding directly on the item.

However, rest assured that all our products undergo rigorous quality checks and are backed by Racext’s commitment to performance and reliability.

📅 EXCLUSIVE MANUFACTURING AND DISTRIBUTION

Our trusted partners manufacture each product according to our specific technical requirements, ensuring that every item meets Racext’s high standards. All our products are exclusively sold by Racext and are not distributed by other companies.

Even though some of our partners commercialize similar products for cars, these items are not compatible with motorcycles due to distinct resistance and amperage requirements.

🔧 PRECISION-CALIBRATED CHIP TUNING DEVICES

When it comes to our chip tuning devices, the resistance is precisely calibrated to be perfectly adapted to different vehicles, such as motorcycles. This ensures optimal performance, compatibility, and a smooth ride without any risk to your vehicle’s electronic systems.

Racext chip tuning devices are specially designed to meet the unique demands of motorcycle performance systems, guaranteeing that your bike runs efficiently and reliably.

⚠️ Legal Notice – Important Product Disclaimer

This product is not certified, approved or homologated for use on public roads or highways in any country. It is intended solely for off-road use, closed-circuit racing, sports competition, or private testing purposes. Installation and use of this product on vehicles driven on public streets is strictly prohibited and may violate traffic laws, emissions regulations, or technical inspection requirements.

By purchasing this product, the customer acknowledges and agrees that:

- The product is sold “as is” for motorsport or off-road use only.

- It is not street-legal and must not be used on public roads under any circumstance.

- The seller (Racext) assumes no responsibility for any improper, illegal or unintended use of this product.

- The customer is solely responsible for verifying whether the installation and use of this product comply with local laws and regulations.

- This product may affect vehicle warranty and insurance if used outside of permitted contexts.

This notice applies regardless of the country in which the product is purchased or shipped, including (but not limited to) the United States, Canada, the European Union, the United Kingdom, Australia and New Zealand.

By proceeding with the purchase, you confirm that you have read, understood and accepted this disclaimer, and release the seller from any liability arising from misuse or unauthorized application of the product.

🔒 QUALITY STANDARDS ACROSS ALL PRODUCTS

This high standard of exclusive design, manufacturing, and compatibility applies to all Racext products available for purchase. Every item in our catalog is crafted with the same dedication to performance, safety, and quality.

🔧 PERFORMANCE YOU CAN TRUST, QUALITY YOU CAN SEE

Disclaimer

TRANSPARENT SHIPPING POLICY

Cutoff time 22:00 (GMT+01:00) Central European Standard Time (Amsterdam)

Order Processing Time 1-3 days (Mon-Fri)

Delivery time 3-6 days (Monday-Friday)

Our orders are free of shipping costs.

We use the following shipping couriers:

- PostNL

- Dhl

- UPS

- DPD

- Cainiao

The customer will receive the tracking information in 1-3 days directly in his email. Please contact us if you have not received the email or check your spam emails

LEGAL DISCLAIMER: PRODUCTS INTENDED EXCLUSIVELY FOR SPORTING AND COMPETITIVE USE

Important: Before proceeding with the purchase or use of our sport exhausts, please read the following notice carefully.

The products sold through this website are intended exclusively for sporting and competitive use. This means they have been designed and manufactured to be used in controlled environments, such as closed circuits or areas designated for sporting competitions, where emission and noise regulations may differ from those applied on public roads.

Public Road Use Not Allowed: It is emphasized that the installation and use of these devices on vehicles intended for circulation on public roads may not be permitted under the laws of your reference country regarding emission and noise regulation, as they are not designed for road use but for sporting use.

Buyer’s Responsibility: It is the buyer’s responsibility to ensure that the use of the purchased products complies with all applicable laws and regulations. The buyer assumes all legal liabilities for any non-compliant use of the products, including the installation and operation of such devices on unauthorized vehicles or in ways that violate applicable laws.

By continuing with the purchase, the buyer acknowledges and agrees that the use of the products is limited to sporting and competitive contexts as defined above and assumes full responsibility for any legal consequences arising from improper use of the products.

How to push back brake piston without tool

Compatibility:

It is the responsibility of the customer to ensure that the product is compatible with their vehicle. We recommend consulting with a professional mechanic before purchasing to confirm compatibility. Racext is not responsible for any issues that may arise from the use of our products, including but not limited to damage to the vehicle or personal injury.

Warranty:

All of our products come with a 2-year warranty in accordance with international standards. If you experience any issues with your product within the warranty period, please contact us for assistance. The warranty does not cover damages caused by improper installation, misuse, or external factors such as accidents or natural disasters.

Returns

ABOUT US

ADDRESS: Creative Tower – Hamad Bin Abdulla Road – Office 4201 – Fujairah – U.A.E.

E-mail : info@Racext.com

Contact form : Get in touch

Phone : +971 58 859 1706

Company name : Digitanow International group FZe

Company Number : AE18048/2020

Tax registration number: AE18048 2020

Customer service : Monday to Friday from 9 a.m. to 8 p.m.

Terms and Conditions

This website provides only the product with well-indicated codes and specifications. Please rely on an experienced workshop for the installation and choice of the product. We do not assume any responsibility for errors in choice, installation, or programming of the devices.

*The price is intended for a single product

*Days are always working days

All guides on this website are for illustrative purposes only. For many products, the use of special tools may be necessary. We always recommend seeking the advice of a specialized repair center for the selection and installation or programming of products purchased anywhere. We do not assume any responsibility for damage to property or persons, or user errors in the application of a guide on this website or for any other occurrence.

Product is not original but fully interchangeable with it

All rights reserved. All trade names and logos are registered trademarks of the respective manufacturers indicated

The trademarks mentioned on this site are the exclusive property of the automotive companies and are used here exclusively to facilitate the search for vehicles by our customers. We do not assume any responsibility for damages to property or persons, or user errors in the application of a guide on this website or for any other occurrence.

Secure Payments

When making purchases on our website, you can be confident that your transaction is secure. All financial transactions are processed on the secure and certified servers of PayPal or Stripe. These platforms allow us to accept payments from all VISA, VISA ELECTRON, MAESTRO, POSTEPAY, AMERICAN EXPRESS, AURA, and DISCOVER credit cards.

Quality Guarantee

Choose safety, savings, and professionalism by choosing us. We offer top-level customer support that will never leave you alone during the pre- and post-purchase phases. We offer top-quality products and intelligent, secure savings. Don’t trust inexperienced sellers.

NOTE: In the event that the product is not available in stock, we reserve the right to issue a full and immediate refund.

[mailpoet_form id=”3″]