Car Magazine

How much do welders make? The truth on welder salary

How much do welders make? The truth on welder salary – on our site you will find the best spare parts and accessories for cars and motorcycles

SELECT YOUR VEHICLE'S BRAND AND MODEL TO FIND ALL COMPATIBLE PRODUCTS ON RACEXT.

✅ Choose free delivery to save more

How much do welders make? The truth on welder salary

Before purchasing our products, it is advisable to read the product sheet. If in doubt, do not hesitate to contact us, we will be happy to help you choose the product that best suits your needs

If you are looking for high quality products for your car or motorbike, look no further. We are sure you will find the perfect product for you at Racext. Do not hesitate to contact us with any questions or requests. We are here to help you make your vehicle perfect.

In the face of a shortage, it is natural to witness a rise in costs. This principle aligns with basic economics: when a highly demanded resource is limited in supply, consumers can anticipate paying higher prices compared to periods of lower demand or abundant availability.

Over the past few years, welders have found themselves perplexed by the consistent clamor in their industry regarding a shortage of skilled workers. According to the American Welding Society, it is estimated that the U.S. industry will face a shortage of more than 450,000 competent welders by 2022, which is undoubtedly a substantial deficit (as reported by the Bureau of Labor Statistics, there were nearly 425,000 welding jobs in existence in 2018). Consequently, one might consider this scarcity as an opportune time for wages to increase, given the impending shortfall.

Complicating matters further are the voices of pundits and the vast expanse of the internet. After hearing numerous accounts, it is possible to be misled into believing that the starting salary for a welder is $40,000. This figure is commonly thrown around; however, it represents the median salary. The Bureau of Labor Statistics reports that the median annual salary for welders in 2018 was $41,380. It is crucial to understand that the median denotes that 50 percent of welders earned less than this amount, while the other 50 percent earned more. Adding to the confusion, an editorial titled “Welders Make $150,000? Bring Back Shop Class” was published in The Wall Street Journal in April 2014, which continues to exist as propaganda enticing young individuals to pursue welding, even though it focused on a specific type of welder and their specialized skill set. Additionally, it is worth mentioning those who search “underwater welder salary” on the internet. If an underwater welder can earn $300,000 in a year, then surely a welder on land can make half of that, right?

The reality of the situation is that welders can earn a decent living, even at the entry level, but they generally won’t immediately command top dollar. Like any profession, most individuals must start at the bottom and work their way up.

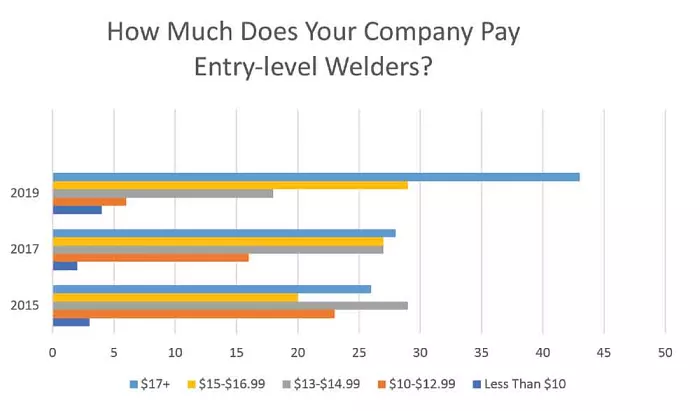

While wages are indeed increasing, they may not be rising at a rate that matches the hype surrounding the shortage of skilled workers. The WELDER, a sister publication to The FABRICATOR, conducted readership surveys in which subscribers were asked about the hourly pay for entry-level welders at their respective companies (see Figure 1). In 2015, only 26 percent of respondents reported paying more than $17 per hour. By 2017, this figure had risen to 28 percent, and in the most recent survey, conducted this year, it reached 43 percent.

Rob Abfall, the chief operating officer of Amerequip Corp., a fabricator specializing in custom equipment for the lawn, landscape, agricultural, and construction markets, revealed that the company struggled to attract and retain workers in 2017 and early 2018. This situation led them to turn down work opportunities. Between 2012 and 2017, the company’s workforce grew from 125 employees to 300. To stabilize the workforce later in 2018, one of their initial steps involved increasing wages.

“We renegotiated the contract with the International Association of Machinists and Aerospace Workers union and implemented more significant raises than initially agreed upon,” Abfall explained.

Amerequip raised starting wages to more than $15 per hour and elevated starting wages for welders to over $18 per hour. This wage increase, coupled with an agreement to introduce a weekend shift that offered 40 hours of pay for a 36-hour shift spanning Friday, Saturday, and Sunday, helped stabilize the workforce. This stabilization allowed management to concentrate on filling open production capacity and improving efficiency to introduce new capacity.

The need to boost welder wages is not limited to Kiel, Wisconsin, where Amerequip is located. With Amazon establishing distribution centers nationwide and many metropolitan areas adopting a minimum wage of $15, fabricating companies have been compelled to raise wages. As indicated by The WELDER’s readership survey, companies have had to take aggressive measures to adjust wages in order to attract entry-level workers.

Of course, this is only one aspect of the story concerning welders and their earning potential. Let’s explore additional factors that contribute to determining the expected income for welders.

Figure 1

Over the past five years, the number of shops paying welders at least $17 per hour has risen dramatically.

Experience Impacts Welder Salary

The few occasions you tinkered with your father’s welding power source in the garage during your childhood cannot be considered as legitimate welding experience. However, many individuals still believe they are fully prepared to dive into the field of welding.

Nevertheless, reality has a way of dispelling such notions. To truly unlock the earning potential of welding, one must invest time and effort into honing their skills.

This notion may not align with the stereotype attributed to millennials, who currently comprise the largest generational cohort in the U.S. workforce, totaling 56 million individuals according to the Pew Research Center. Often driven by a desire for immediate financial gratification, they may lack the necessary experience and expertise to warrant such remuneration.

Scott Mazzulla, the president and CEO of the Hobart Institute of Welding Technology in Troy, Ohio, sheds light on this phenomenon. He notes that unrealistic expectations of aspiring welders seeking underwater welding careers solely for the pay quickly fade once confronted with the realities of the profession.

Mazzulla emphasizes the strength of the current job market, citing the high quit rate as evidence. The U.S. Labor Department reported a post-recession peak in the quit rate in July. Mazzulla’s discussions with alumni from the Hobart Institute further corroborate these findings.

He explains, “Today, they can offer you what you want, or they can probably find a job elsewhere that pays a dollar or more per hour because the demand is so high.”

Ryan Blythe, the founder of the Georgia Trade School in Acworth, Georgia, shares insights gained from eight years of training welders at his private technical institution. Blythe has witnessed the rewarding prospects that await welders who dedicate themselves to their craft over several years. It is not uncommon for successful alumni to earn $30 to $35 per hour.

Blythe observes, “I’ve noticed that graduates from four or five years ago are now buying houses and starting families. In many cases, their situations are far more favorable than their contemporaries who attended college and are currently struggling.”

It remains clear that those who diligently refine their welding skills will find themselves in a more advantageous position than those who do not. Highly skilled welders are more likely to maintain employment even during economic downturns, which are inevitable despite the absence of one in the U.S. for the past 12 years.

Mazzulla asserts, “When the market declines, more people will flock to welding schools. As a result, companies that require, let’s say, 30 welders today might only need 20 when the economy weakens. Consequently, the competition for those jobs will intensify, and the subpar or mediocre welders will struggle to find work due to their inadequate skill sets.”

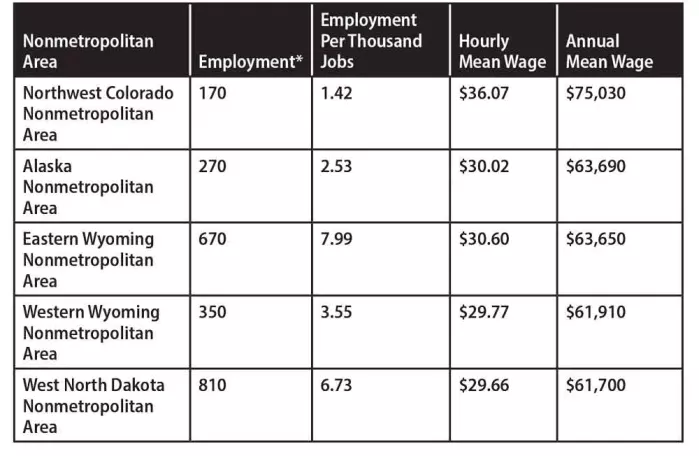

Figure 2

If you want to maximize your salary as a welder, you need to go where there aren’t that many welders or go where there is a need for a lot of welders. Source: Bureau of Labor Statistics for “Welders, Cutters, Solderers, and Brazers,” May 2018. *Jobs number does not include self-employed individuals.

Welding Pay Varies by Job

Are you skilled in welding and open to traveling? You have the potential to earn significantly more money than someone working in a fabrication shop just a short distance from their home.

According to Mazzulla, there are around 2,500 job openings available to graduates of the Hobart Institute, offered by 400 different employers. Some of the positions listed on the job board pay $40 per hour with an additional $85 per diem. These opportunities mainly involve pipeline work, requiring graduates to be willing to travel to where the projects are located.

It’s not uncommon for specialized welding skills to command higher wages compared to positions that don’t require certifications. As an example, the Fabricators & Manufacturers Association’s 2019 Salar/Wage & Benefit Survey indicates that a code welder in the metal fabricating industry earns a median salary of $53,000, which is higher than a welder with only two years of experience, whose median salary is $44,096.

Blythe mentioned that certain companies are transparent about the earning potential for welders. He cited Ingalls Shipbuilding in Pascagoula, Miss., as an example, stating that they clearly communicate to welders that passing a welding test for a specific level guarantees a certain wage. As welders gain more experience, they can take additional skill tests to further increase their pay.

Naturally, wages vary based on geographical location (refer to Figures 2 and 3). Locations such as Alaska and North Dakota offer some of the highest hourly wages for welders, but this is closely tied to the demand for domestic energy production, involving the construction, maintenance, and repair of pipelines and rigs. Hawaii and California also rank among the top 10 states with the highest hourly wages for welders, but the cost of living in these areas is much higher compared to the Deep South states, for example.

Employers Will Pay Higher Welder Salary for Leaders

The discussion surrounding welders’ wages often overlooks or disregards an important aspect: employers are not merely seeking individuals capable of laying down consistent welds. They desire employees who possess punctuality, intellectual curiosity, and strong interpersonal skills. Additionally, passing a drug test is often a requirement.

Over the years, we have observed the remarkable growth of our graduates from 2013 to the present. Employers, particularly those in fabrication shops, now seek individuals who have the potential to become shop managers or foremen. They aspire to find someone who can ascend the professional ladder.

These employers aim to shape their employees into successful contributors within their manufacturing environments. When they discover a skilled worker who fits this profile, they should strive to retain them. This symbiotic relationship should foster contentment for both the employer and the welder.

It is crucial to emphasize the multifaceted nature of welding careers and the importance of attributes beyond technical proficiency. By recognizing and valuing qualities such as reliability, intellectual curiosity, teamwork, and a commitment to maintaining a drug-free workplace, employers can cultivate a workforce that thrives in their specific manufacturing settings. Ultimately, this approach contributes to the overall satisfaction and success of both employers and welders.

🌊 RACEXT QUALITY GUARANTEE

Every Racext performance product is thoroughly tested and guaranteed, even if it doesn’t feature a visible logo. Due to production and logistical reasons, some products may not carry the Racext branding directly on the item.

However, rest assured that all our products undergo rigorous quality checks and are backed by Racext’s commitment to performance and reliability.

📅 EXCLUSIVE MANUFACTURING AND DISTRIBUTION

Our trusted partners manufacture each product according to our specific technical requirements, ensuring that every item meets Racext’s high standards. All our products are exclusively sold by Racext and are not distributed by other companies.

Even though some of our partners commercialize similar products for cars, these items are not compatible with motorcycles due to distinct resistance and amperage requirements.

🔧 PRECISION-CALIBRATED CHIP TUNING DEVICES

When it comes to our chip tuning devices, the resistance is precisely calibrated to be perfectly adapted to different vehicles, such as motorcycles. This ensures optimal performance, compatibility, and a smooth ride without any risk to your vehicle’s electronic systems.

Racext chip tuning devices are specially designed to meet the unique demands of motorcycle performance systems, guaranteeing that your bike runs efficiently and reliably.

⚠️ Legal Notice – Important Product Disclaimer

This product is not certified, approved or homologated for use on public roads or highways in any country. It is intended solely for off-road use, closed-circuit racing, sports competition, or private testing purposes. Installation and use of this product on vehicles driven on public streets is strictly prohibited and may violate traffic laws, emissions regulations, or technical inspection requirements.

By purchasing this product, the customer acknowledges and agrees that:

- The product is sold “as is” for motorsport or off-road use only.

- It is not street-legal and must not be used on public roads under any circumstance.

- The seller (Racext) assumes no responsibility for any improper, illegal or unintended use of this product.

- The customer is solely responsible for verifying whether the installation and use of this product comply with local laws and regulations.

- This product may affect vehicle warranty and insurance if used outside of permitted contexts.

This notice applies regardless of the country in which the product is purchased or shipped, including (but not limited to) the United States, Canada, the European Union, the United Kingdom, Australia and New Zealand.

By proceeding with the purchase, you confirm that you have read, understood and accepted this disclaimer, and release the seller from any liability arising from misuse or unauthorized application of the product.

🔒 QUALITY STANDARDS ACROSS ALL PRODUCTS

This high standard of exclusive design, manufacturing, and compatibility applies to all Racext products available for purchase. Every item in our catalog is crafted with the same dedication to performance, safety, and quality.

🔧 PERFORMANCE YOU CAN TRUST, QUALITY YOU CAN SEE

Disclaimer

TRANSPARENT SHIPPING POLICY

Cutoff time 22:00 (GMT+01:00) Central European Standard Time (Amsterdam)

Order Processing Time 1-3 days (Mon-Fri)

Delivery time 3-6 days (Monday-Friday)

Our orders are free of shipping costs.

We use the following shipping couriers:

- PostNL

- Dhl

- UPS

- DPD

- Cainiao

The customer will receive the tracking information in 1-3 days directly in his email. Please contact us if you have not received the email or check your spam emails

LEGAL DISCLAIMER: PRODUCTS INTENDED EXCLUSIVELY FOR SPORTING AND COMPETITIVE USE

Important: Before proceeding with the purchase or use of our sport exhausts, please read the following notice carefully.

The products sold through this website are intended exclusively for sporting and competitive use. This means they have been designed and manufactured to be used in controlled environments, such as closed circuits or areas designated for sporting competitions, where emission and noise regulations may differ from those applied on public roads.

Public Road Use Not Allowed: It is emphasized that the installation and use of these devices on vehicles intended for circulation on public roads may not be permitted under the laws of your reference country regarding emission and noise regulation, as they are not designed for road use but for sporting use.

Buyer’s Responsibility: It is the buyer’s responsibility to ensure that the use of the purchased products complies with all applicable laws and regulations. The buyer assumes all legal liabilities for any non-compliant use of the products, including the installation and operation of such devices on unauthorized vehicles or in ways that violate applicable laws.

By continuing with the purchase, the buyer acknowledges and agrees that the use of the products is limited to sporting and competitive contexts as defined above and assumes full responsibility for any legal consequences arising from improper use of the products.

How much do welders make? The truth on welder salary

Compatibility:

It is the responsibility of the customer to ensure that the product is compatible with their vehicle. We recommend consulting with a professional mechanic before purchasing to confirm compatibility. Racext is not responsible for any issues that may arise from the use of our products, including but not limited to damage to the vehicle or personal injury.

Warranty:

All of our products come with a 2-year warranty in accordance with international standards. If you experience any issues with your product within the warranty period, please contact us for assistance. The warranty does not cover damages caused by improper installation, misuse, or external factors such as accidents or natural disasters.

Returns

ABOUT US

ADDRESS: Creative Tower – Hamad Bin Abdulla Road – Office 4201 – Fujairah – U.A.E.

E-mail : info@Racext.com

Contact form : Get in touch

Phone : +971 58 859 1706

Company name : Digitanow International group FZe

Company Number : AE18048/2020

Tax registration number: AE18048 2020

Customer service : Monday to Friday from 9 a.m. to 8 p.m.

Terms and Conditions

This website provides only the product with well-indicated codes and specifications. Please rely on an experienced workshop for the installation and choice of the product. We do not assume any responsibility for errors in choice, installation, or programming of the devices.

*The price is intended for a single product

*Days are always working days

All guides on this website are for illustrative purposes only. For many products, the use of special tools may be necessary. We always recommend seeking the advice of a specialized repair center for the selection and installation or programming of products purchased anywhere. We do not assume any responsibility for damage to property or persons, or user errors in the application of a guide on this website or for any other occurrence.

Product is not original but fully interchangeable with it

All rights reserved. All trade names and logos are registered trademarks of the respective manufacturers indicated

The trademarks mentioned on this site are the exclusive property of the automotive companies and are used here exclusively to facilitate the search for vehicles by our customers. We do not assume any responsibility for damages to property or persons, or user errors in the application of a guide on this website or for any other occurrence.

Secure Payments

When making purchases on our website, you can be confident that your transaction is secure. All financial transactions are processed on the secure and certified servers of PayPal or Stripe. These platforms allow us to accept payments from all VISA, VISA ELECTRON, MAESTRO, POSTEPAY, AMERICAN EXPRESS, AURA, and DISCOVER credit cards.

Quality Guarantee

Choose safety, savings, and professionalism by choosing us. We offer top-level customer support that will never leave you alone during the pre- and post-purchase phases. We offer top-quality products and intelligent, secure savings. Don’t trust inexperienced sellers.

NOTE: In the event that the product is not available in stock, we reserve the right to issue a full and immediate refund.

[mailpoet_form id=”3″]

Arabic

Arabic Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch English

English French

French German

German Greek

Greek Italian

Italian Japanese

Japanese Maltese

Maltese Norwegian

Norwegian Polish

Polish Portuguese

Portuguese Romanian

Romanian Serbian

Serbian Slovenian

Slovenian Spanish

Spanish Swedish

Swedish